Working on BlackSheep II during my Christmas vacation. A fair bit has happened since my last post. I'll try to bring the thread up to date.

Of course dealing with the rust is a big part of my work right now. With my last post I had removed the rear axle to allow better access to the back part of the frame where the crossmember is quite rusty. When I got back out there this past saturday, my goal was to get the body re-attached and try to tilt it forward. The goal in that is to give myself a bit more space to clean up the top side of that crossmember.

As I started working towards getting the bolts up through the new body mounts I realized that the body had shifted forward about 3/4". It took a while but I was able to slide the body backward by pulling on the body while hammering the base of the jack stand. Four jack stands supporting the body had to be moved about 3/4" each. That was fun. Anyway, I got the bolts to line up. There are 6 mounts in the main part of the body, between the wheels - three on each side. I assembled the three mounts and threaded the bolts through there just enough to ensure good thread engagement. For the two most forward mounts, I assembled them completely with all of the parts including the spacer and the rubber bushing that goes on the bottom side of the frame portion of the body mount.

Maybe it's hard to see in that image but the body is resting on the most forward mount (left side of screen) and the jack stand is supporting the body near the third mount which you can see results in about 5" between the body and the frame at the very back of the body. All six of those body mounts are between the body and the frame and all six bolts are threaded in.

With the axle and the gas tank pulled I can actually really get back there to attack the rust.

There is still work to be done here but with some new sanding disks I purchased, the work is going pretty fast. There is also a bunch of dust from the clean-up hanging around on that part as well. I'm pleased with how easy / accessible this bottom side is, the real question is the top. I'll dig into that tomorrow.

I hit some of the easy access places as well once I got the new sanding disks in play:

The rust work is ongoing, did some Saturday, did some Sunday and today I did a bunch! Plenty left to do.

The other thing my buddy Scott and I did this weekend was to pull the front axle. As with the rear axle, pulling the front allows me to address some light rust situations up front. Not as bad as the back but it will def be easier without the axle. Another part of this is the rust / finish of the axle itself. with it outside the Jeep it will be easier to clean up and paint the axle housing. That will make me feel better - all kinds of new parts need to have the 'old' parts cleaned up.

Speaking of new parts...

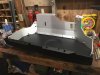

That's not fully unpacked yet - one more box to the right of the image contained the shocks, bump stops, hardware, etc. Anyway you can see the bulk of the MetalCloak 3.5" short arm kit. To the left lower is the rear upper spring perch relocation kit. Wrapped in all that plastic on the left are the parts for the gas tank skid plate. It is also a MetalCloak part. Super beefy! but also three of the four 'walls' of the skid are aluminum.

Anyway, rust removal and painting before I can really start re-assembling.