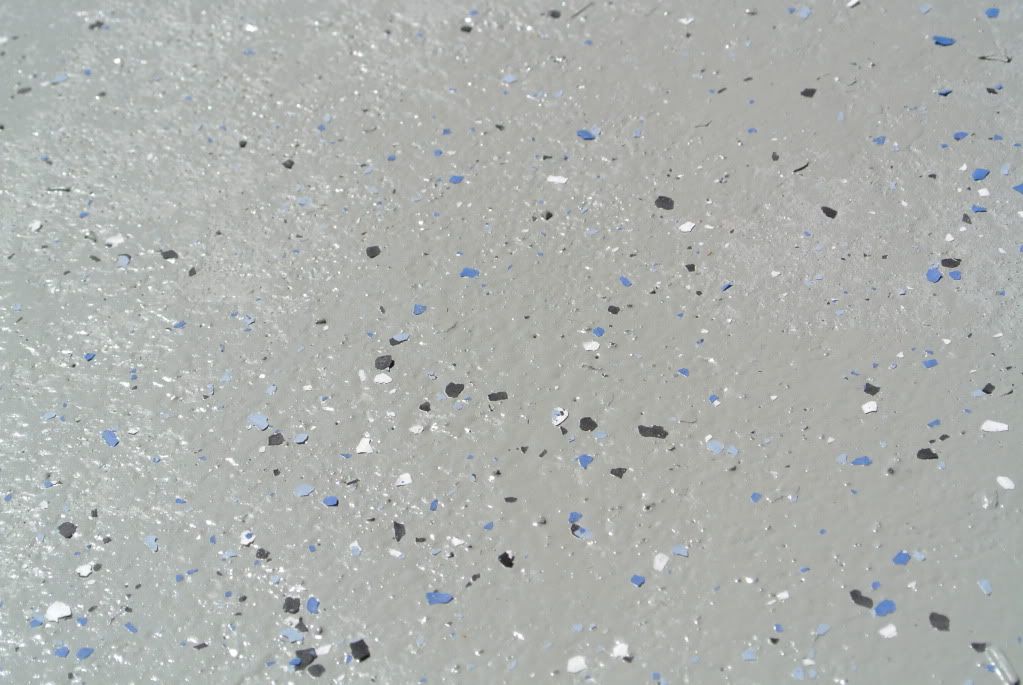

I'll have to verify the brand I used but I think it was Rustoleum from Lowes. I've had it five (almost six) years now and it still looks fantastic. Every spring I empty my garage and power wash the entire thing and it looks brand new when I'm done. I will say that the longevity of whatever you use will be determined by the prep you put in to it before hand. I used the acid etching stuff (muraic acid or something like that) and I had my builder leave my garage floor a broom finish. I used three cans for my three car garage and have been super happy with it. If I were to do it again, I'd would probably do the same stuff again given that I was only into it ~$300 and it's lasted as well as it has. The only places I'm getting any chipping is right at the front of my garage, about 2" of the painted floor is outside the garage, so that 2" of painted floor gets shoveled, snow blow(ed?), and exposed to all the elements and I am seeing a little bit of flaking there, other than that it looks almost brand new.

Any painted floor (wether it's super expensive epoxy or the DIY HD/Lowes stuff) will melt if you weld on it...however, it's not like it instantly melts. I've used my chop saw, grinder, etc without any issues at all.