I am not a machinist And the only prior (minimal) lathe experience I have have had is using a mini lathe for really basic and non critical stuff at an old job.

Anyway, I've been wanting to get a lathe forever because I realized how much it would expand my capabilities in making things. I didn't want to spend ton or have room for a very big machine, so after some research I saw that the 7x mini lathes can be made decent for hobbyist use with a little upgrading. I ordered the 7x12" lathe from the harbor fr8 website on black friday, and wish I would have done so years ago.

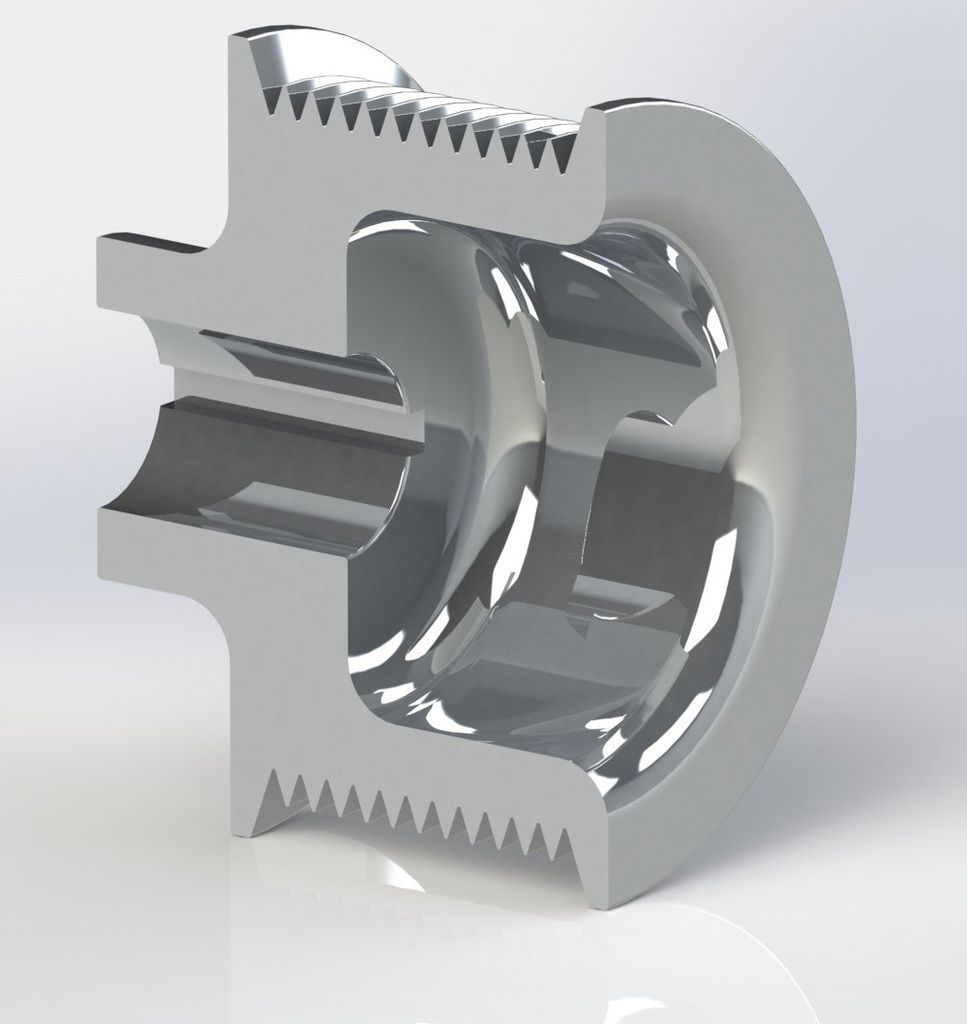

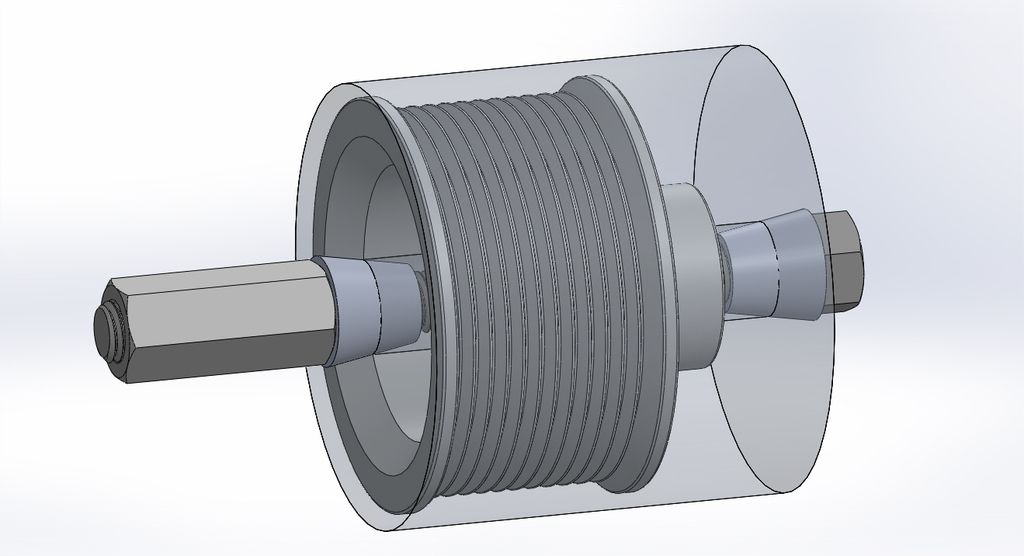

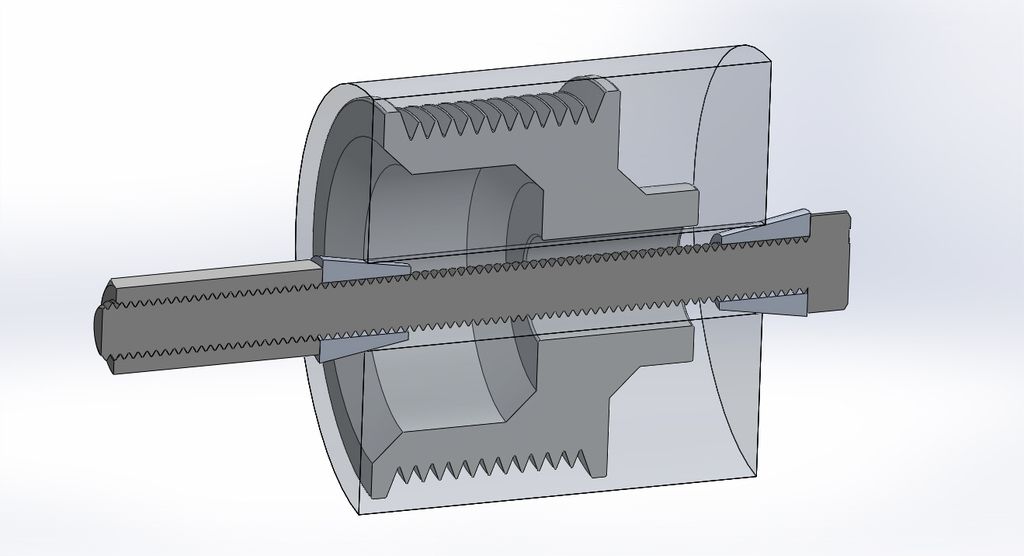

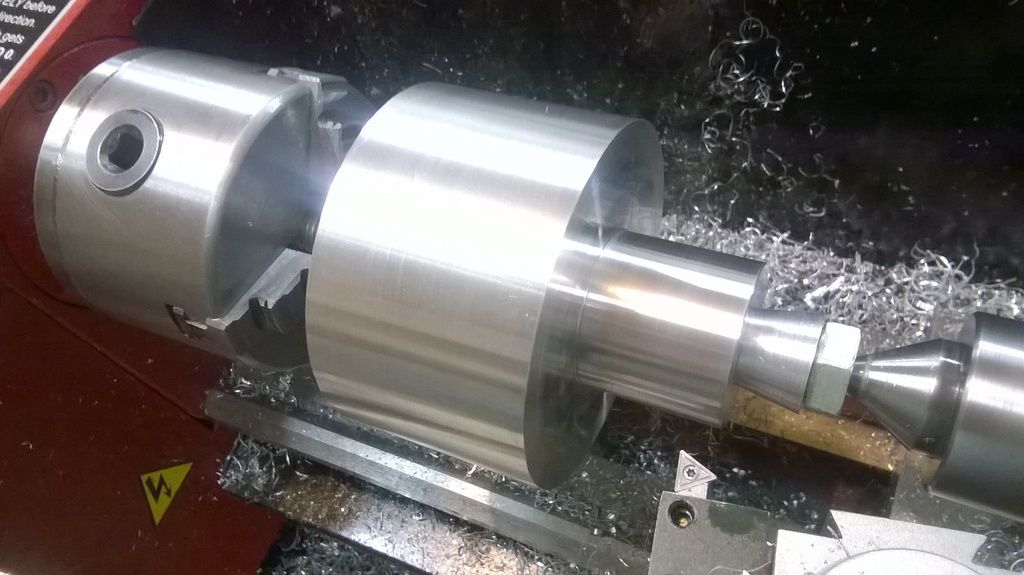

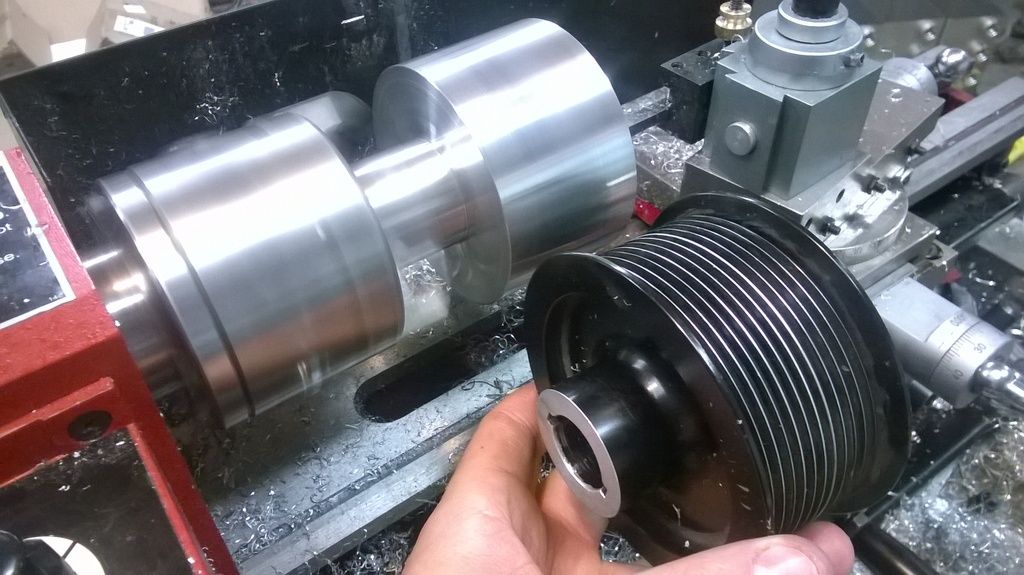

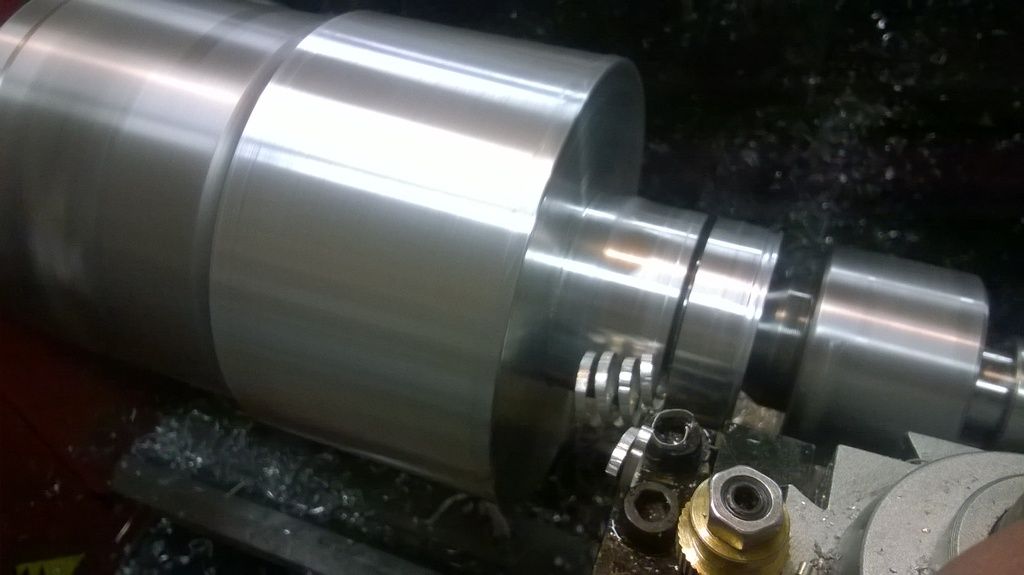

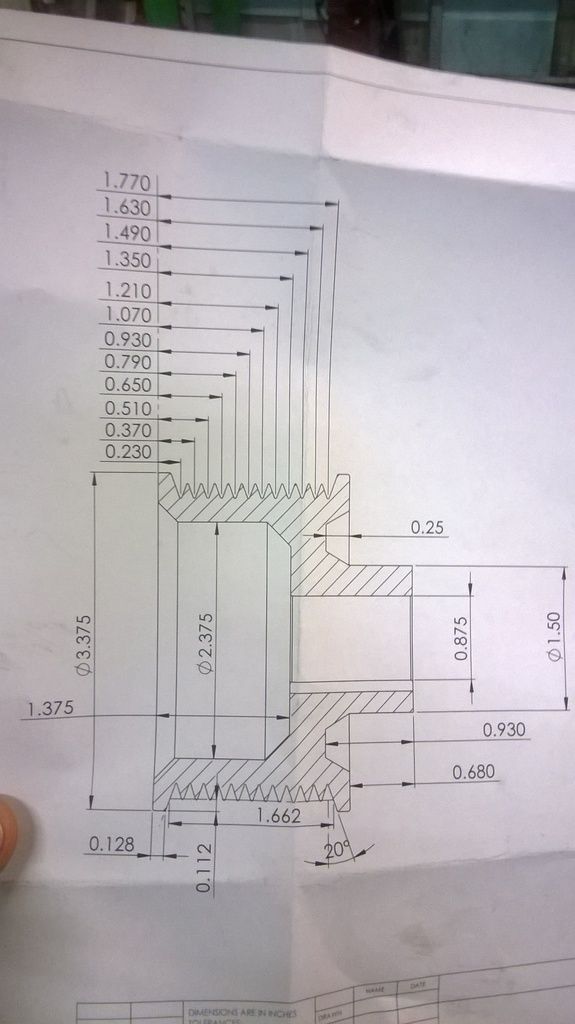

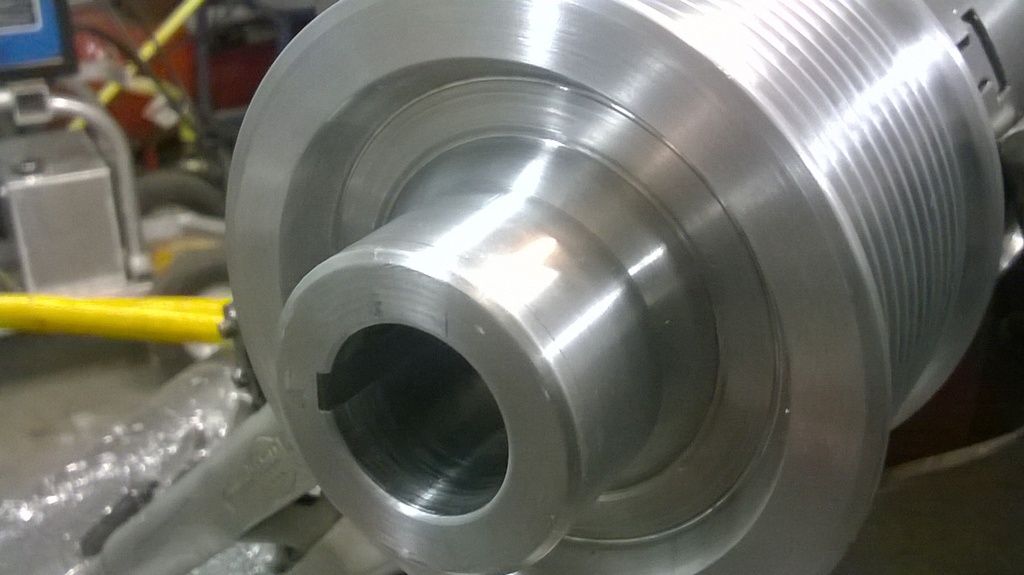

My first project is to make a supercharger pulley for my friends Procharged Camaro. He's currently running a 3.7" pulley and seeing about 11psi of boost on his 383. We are making a 3.2" pulley.

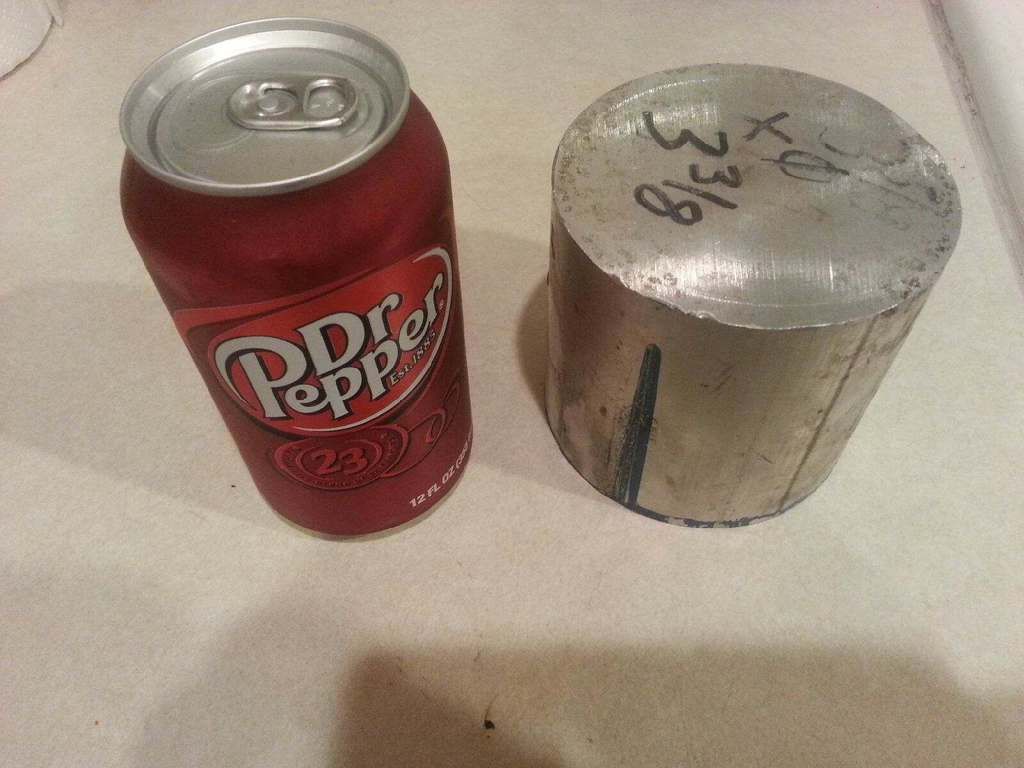

We bought a slug of aluminum on ebay for like $24 and while it was shipping I started familiarizing myself with some basic lathe operations.

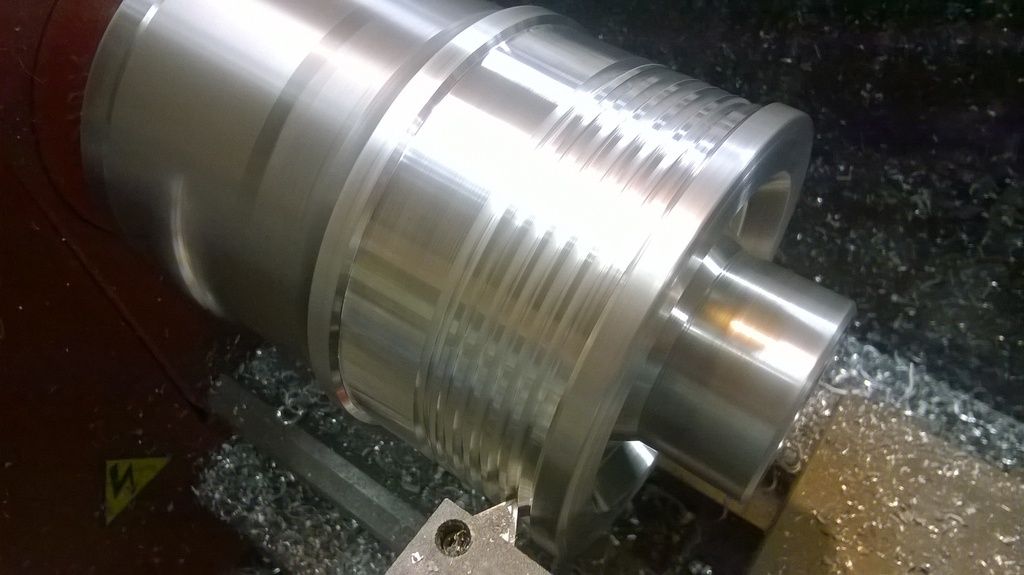

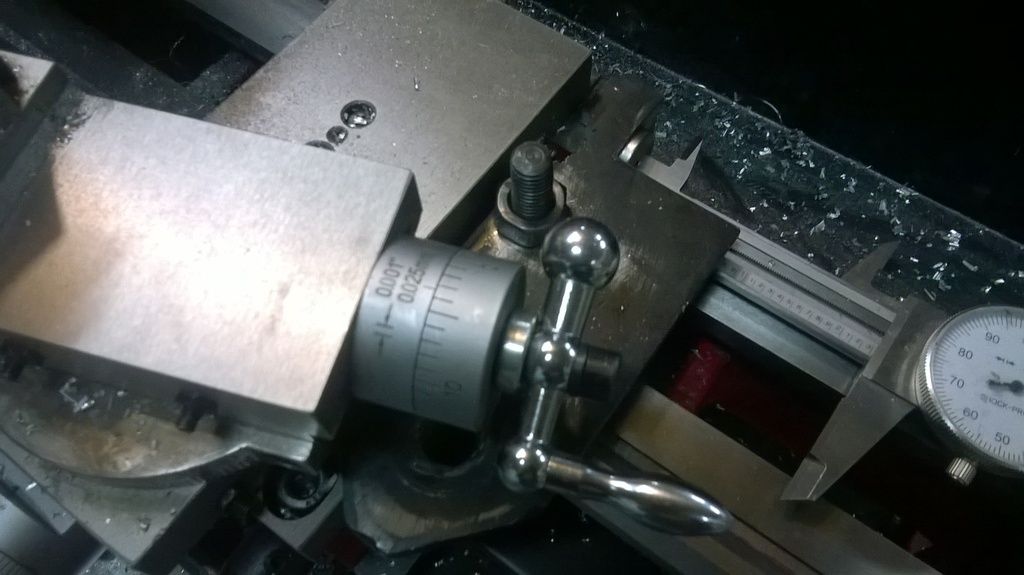

Here's some testing out turning, facing, parting, threading, drilling, boring.

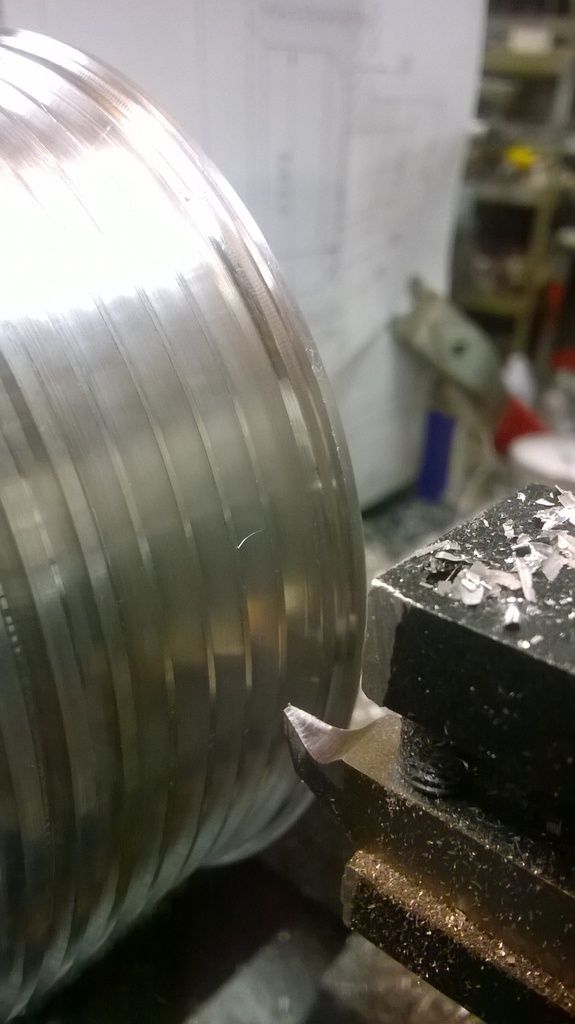

testing making 20tpi threads on a 1/2" aluminum tube (with a carbide tool that's not quite the correct geometry for this thread)

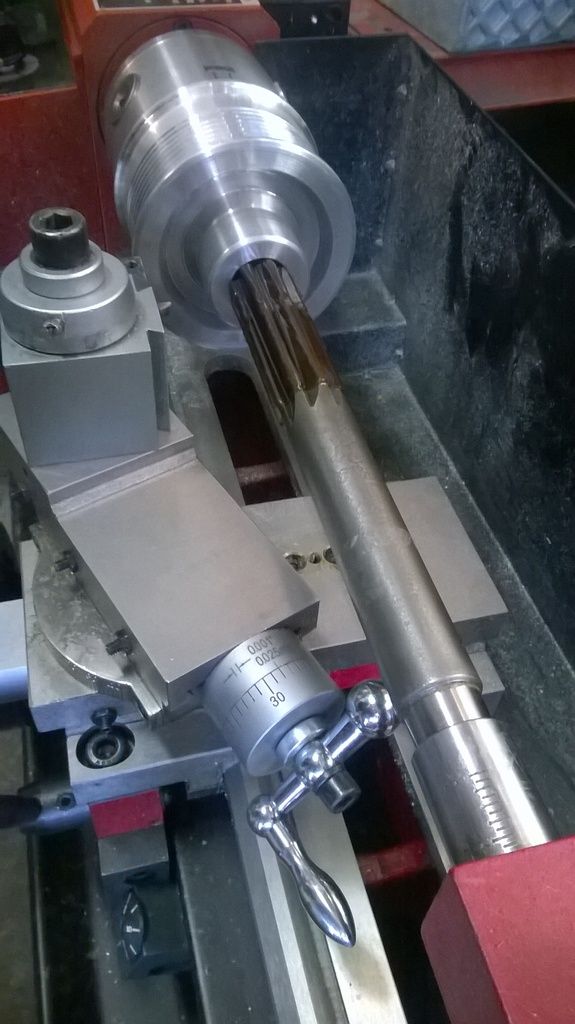

testing turning and parting in aluminum

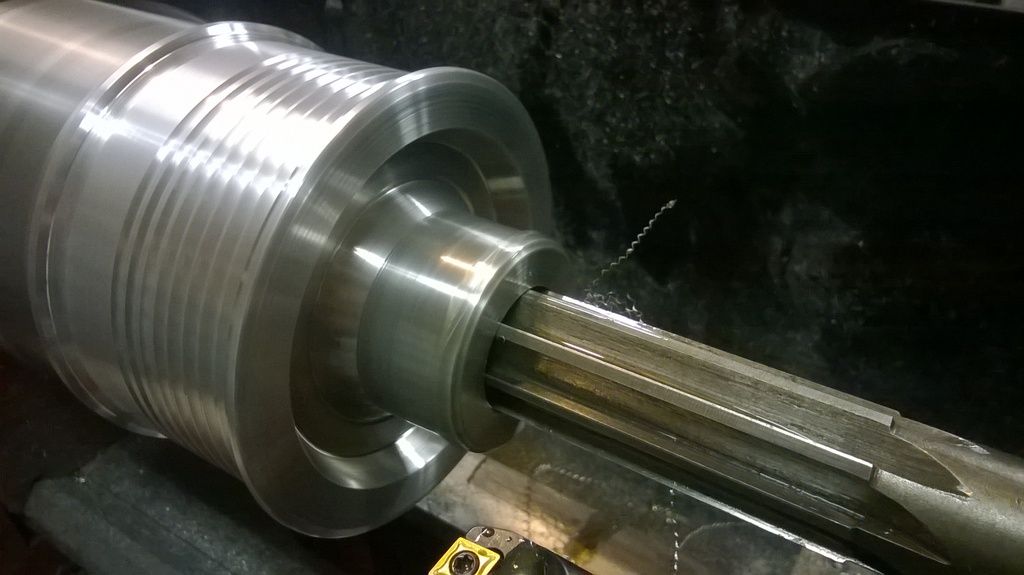

testing threading in steel with an appropriately ground HSS tool

Anyway, I've been wanting to get a lathe forever because I realized how much it would expand my capabilities in making things. I didn't want to spend ton or have room for a very big machine, so after some research I saw that the 7x mini lathes can be made decent for hobbyist use with a little upgrading. I ordered the 7x12" lathe from the harbor fr8 website on black friday, and wish I would have done so years ago.

My first project is to make a supercharger pulley for my friends Procharged Camaro. He's currently running a 3.7" pulley and seeing about 11psi of boost on his 383. We are making a 3.2" pulley.

We bought a slug of aluminum on ebay for like $24 and while it was shipping I started familiarizing myself with some basic lathe operations.

Here's some testing out turning, facing, parting, threading, drilling, boring.

testing making 20tpi threads on a 1/2" aluminum tube (with a carbide tool that's not quite the correct geometry for this thread)

testing turning and parting in aluminum

testing threading in steel with an appropriately ground HSS tool

Last edited: