ZUKEYPR

Registered User

- Location

- 651.78 miles East of the Rubicon

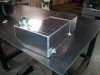

Does anyone know of an aftermarket company that makes an aluminum slider such as the one shown here http://www.bigdaddyoffroad.com/product_info.php?products_id=96

for a TJ/LJ that the step kicks out further. The one on the link is pretty much useless as a step due to the narrowness of it.

If not would there be any business locally who could bend the 6061-T6 to the shape of what I am referring to? I know gen right makes precisely what I'm looking for, but not for the TJ's.

Thanks

for a TJ/LJ that the step kicks out further. The one on the link is pretty much useless as a step due to the narrowness of it.

If not would there be any business locally who could bend the 6061-T6 to the shape of what I am referring to? I know gen right makes precisely what I'm looking for, but not for the TJ's.

Thanks