- Location

- Grand Junction, CO

How big is your plasma table, Carl?

4.5' x 5.5'How big is your plasma table, Carl?

I actually just picked up a mag drill a few days ago, that's kinda what spurred this whole discussion.I'm not completely sold on a table full of holes for what I do. I know many who have them drilled like swiss cheese and on as small as 2" centers. If that fits your needs then I understand but I worked on a friends table that was on 3" centers and it drove me nuts. We weren't fixturing anything, I was helping him work on his small generator and he had it sitting on his table. It really messed with my OCD every time I set a tool or screw down.

My fabrication table has been "holeless" for the past 15 years. Mainly because I also use it for more than solely fabrication/fixturing so I didn't add any holes, that is until this year. Over the summer I had a job come into the shop where I was welding some large weldments and was having a difficult time clamping them down in the middle of the table. I will usually do most of my clamping around the perimeter so no need for clamping in towards the middle but this job was a bit different and it got me thinking that I wished I had a few holes spaced throughout the middle of the table for clamping.

I had also been contemplating a mag drill so when my local welding supply had them on promo I bought one and decided to try it out by adding a few holes to my fabrication table.

Laying out the table. The blue tape represents the structure under the 1/2" top.

I also drilled and tapped a few holes for my axle fixtures to bolt to the table.

I purchased some F-clamps and cut/modified about a half dozen for slip fit into the 5/8" holes and so far they've been working well. I like the spacing and doubt I'll add any more holes as so far these seem about right for the work I do. I have a couple of smaller fixturing plates that I used when I was building sand drag quads and sand rails for things like suspension components that I merely set on top of my table and can bolt to them so no need to add more holes to my table at this point.

Mike

fireballtool.com

fireballtool.com

Your on.I didn't want to imply that I deserve to be one of the select few but I was planning on challenging anybody who gets in my way to a tall-off or perhaps a Native American leg-wrestling tournament.

Your on.

www.facebook.com

www.facebook.com

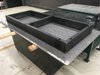

Messaged this guy on FB to buy a table fab table but I was too late. He is willing to get another batch made up if anyone's interested. I told him Id spread the word.

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.www.facebook.com

lol is that guy just straight copying Certiflat tables and selling them?Messaged this guy on FB to buy a fab table but I was too late. He is willing to get another batch made up if anyone's interested. I told him Id spread the word.

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.www.facebook.com