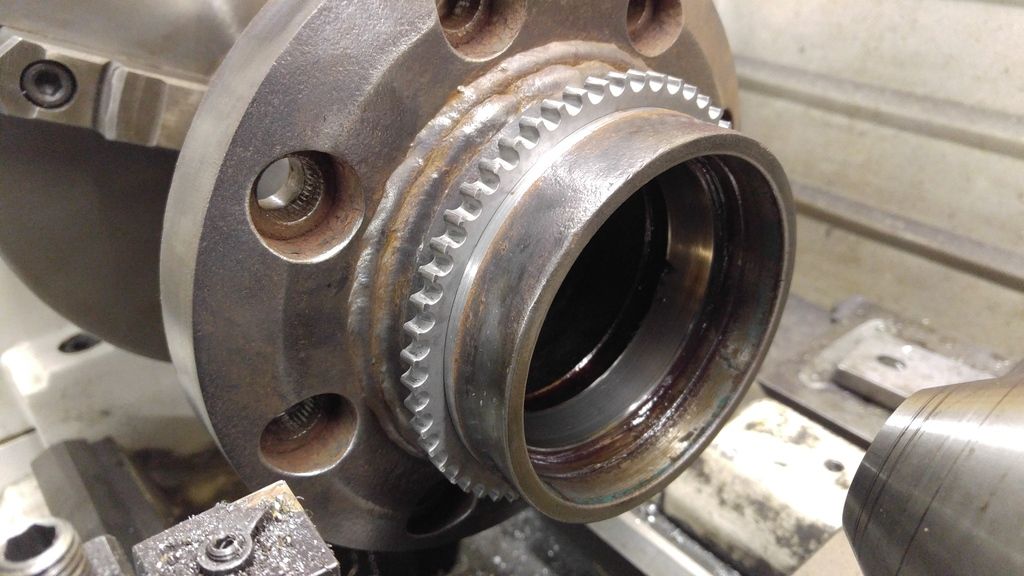

Because I'm using dana 60 shafts I can use a 60 inner axle seal. I made an adapter that the seal fits in that I can press on to the tube. I put a few stitch welds to hold it in place and then put rtv around it to make sure it seals. On a side note next time I do this I'll make the seal adapter wider so the seal is closer to the carrier. There is only about .250" Of sealing area on the outside of the seal the way it is now. I would have liked to have it more in the middle of the seal area on the shaft for next time.