On my turbo camaro I was always irked by the fact that the underhood temps would just reheat the air out of the intercooler.

If I drove around in boost and quickly got out and felt the inlet and outlet of the intercooler the difference was staggering. The inlet was hot like the valve covers, and the outlet was cool like a piece of aluminum in the shade. If you then felt the intercooler outlet tube at the throttle body it had regained some of it's heat.

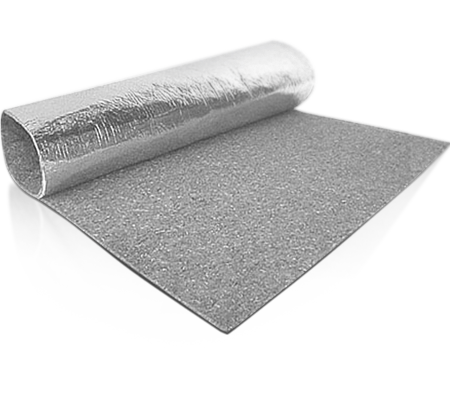

The best practice would be to use a thermally conductive pipe from the turbo to the intercooler to aid in heat transfer, and then to use a thermally non-conductive pipe from the intercooler to the engine because you don't want heat to transfer across the barrier after the air has been cooled. I'm going to use an aluminized fiberglass pipe wrap heat shield on my intercooler-to-engine pipe.

Here's the pipe on the car, fairly exposed to the underhood temps.

And off the car

What I should use is a heat barrier with a fiberglass of felt like layer to insulate heat transfer, and a aluminized or gold layer on top to reflect heat.