Death Start Build Part #6 - Time to put this thing to bed and go to bed myself

Sunday was fairly low key, after burning the candle at both ends on both Friday and Saturday nights, we were hoping Sunday was going be a cakewalk. The main agenda items were finishing up the wiring to the rear fridge and auxiliary outlets in the rear drawer system as well as work on the Helton shower install. I recruited Cody to help me pull wire from the engine bay to the rear drawers. Cody did a fantastic job tucking it all under the trim and looming it from front to back, leaving a super clean look throughout the cab. We terminated the wiring within the side panels of the drawer system and utilized flush mount plugs for the ARB fridge plug, 12V accessory plugs and the dual USB plug as well. The location of the ARB fridge plug was dictated by the location of the fridge slide but the extra 12V and USB ports just made logistical sense. Not only do they serve the needs from the back of the truck but they are super easy to utilize by those in the 2nd row seating, eliminating cords running from the dash to the backseat.

The Helton Hot Water system took a little more time. I have previously installed a handful of Helton systems in 100's belonging to customers but it was always done right against the firewall above the passenger side fender well, unfortunately rightwhere the dual battery is positioned in my particular setup. This required a change of plans as I had the Slee dual battery tray mounted and an ARB compressor mounted right next to the auxiliary battery. After a bit of scoping out and measuring up we found the most copacetic configuration was right behind the shroud of the engine, tucked high against the firewall. While this made for some creative plumbing restraints I was able to tie into the factory coolant system with two additional hoses and if I ever need to remove the Helton, a single OEM hose takes it out of the loop. For the fresh water lines to the bumper I opted for some high temperature rated 1/2" hose in red and blue coloring, the red for the hot (output) side and the blue for the cold (input) side of the system. These lines mate to the Helton bumper fitting bracket thus allowing easy of use in the field.

Plumbing the Helton

Helton Mounted

Helton Bumper Fittings

Rear 12V Plug Wiring

Finalized plug configuration

Bluesea Fuseblock

Finalized Dual Battery & ARB Compressor Mounting & Wiring

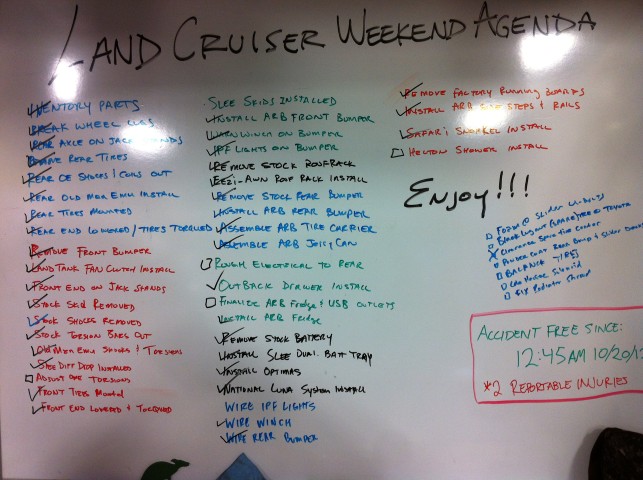

To Do List By End of Day 3 (Sunday 8AM - 5PM):

Inventory Parts

Break wheel lug nuts

Rear End on Jack Stands

Remove Rear Tires

Rear Stock Shocks & Coils Removed

Rear OME Suspension Installation

Rear Tires Mounted

Rear End Lowered & Rear Tires Torqued

Remove Front Bumper

LandTank Fan Clutch Installation

Front End on Jack Stands

Stock Skid Plate Removed

Stock Shocks Removed

Stock Torsion Bars Removed

OME Shocks & Torsion Bars Installed

Slee Diff Drop Kit Installed

OME Torsion Bars Adjusted

Front Tires Mounted

Front End Lowered & Front Tires Torqued

Stock Trans Cross Member Removed

Slee Skid Plates Installed

Install ARB Front Bumper

Warn Winch Installed in Bumper

IPF Lights on Bumper

Remove Stock Roof Rack

Remove Stock Rear Bumper

Install ARB Rear Bumper

Assemble & Install ARB Wheel Carrier

Assemble & Install ARB Jerry Can Holder

Rough Electrical to Rear

Rear 3rd Row Seats & Seatbelts Removed

Outback Drawer System Installed

Finalize ARB Fridge Wiring & Aux power outlets

Install ARB Fridge

Remove Stock Battery

Install Slee Dual Battery Tray

Install Optimas

National Luna Dual Battery System Installation

Remove Factory Running Boards

Install ARB Side Steps & Side Rails

Install Eezi-Awn Roof Rack

Safari Snorkel Installation

Helton Hot Shower System Installation

100% complete, done, finished. While I was fully confident in our ability to make it happen on such a condensed schedule, I was still a bit in awe that all the pieces came together so nicely.

Helpers:

Helpers:

I couldn't have done it without my crew of ringers. These guys all sacrificed parts of their weekend to come slave away on what most considered an impossible build. In the end with many helping hands the actual work load was relatively light and I don't think anyone felt too burned out. We were able to cram nearly 150 man hours worth of projects and installs into a 72 hour window of time and still get a bit of shut-eye in between, all due to the generosity of my pals. I have to lead off my list (which is alphabetical) with my wife Candace who not only put up with my wrenching all weekend but also helped with key components of the build such as parts pickup and even more important feeding the hungry crew.

Candace Williams

Chris Peterson

Cody McKendrick

Corey Fillmore

Dan Lockington

Darren Webster

Dave Connors

Devin Baumgardner

Jake Chatwin

Jason Goates

Johnny Cassel

Josh Stanfield

Kirk Farrell

Olly Bradsteeet

Paul May

Ryan Davis

Scott Jackson

Stephen Nielson

Tovin Benson

(Anyone I'm missing? Please chime in!)

Companies:

While there were many companies that we could have used or did use for different roles on the build, these ones really stood out both in their interest of the project and their ability to help us make it happen on such an abbreviated schedule. I wouldn't hesitate to recommend any of them for your build needs, tell them I sent you

ARB USA - Bumpers & OME suspension

Armor Coatings - Power coating of wheels, bumper and step components

Big-O Tires Sandy - Tires, mounting and balancing.

Equipt Expedition Off-Road - Roof rack and dual battery system

Slee Offroad - Skid plate system, battery tray and diff drop kit.

Ajik/Landtank - Modified fan clutch

Pfran - Interior LED retrofit kit.