Update time!

The 100 has been serving me most splendidly, I've had it out on a dozen or so trips since my last update and each time I grow fonder of its cross-section of abilities and comforts. To further emphasize my absolute pleasure, I finally committed to selling my beloved Tacoma and it now resides with a new owner,

more on that here. With nearly 180k on the clock and little service history beyond the minimal service records I could find in the glovebox, it was time for the 90k service including timing belt, water pump, thermostat, etc. I'm fortunate to have Toyota mastertech and 100 guru Will C. in my neck of the woods and was able to recruit him to rock-out the upkeep. He's done a grip of these services and makes quick work of the project. Thanks again Will

During that same time, I did some minor maintenance on the front end, lower ball-joints, upper ball-joint boots and sway-bar bushings & front links as mine were hammered.

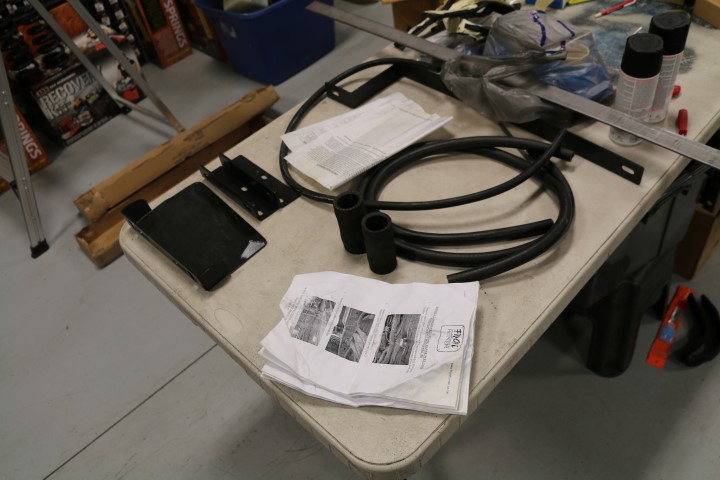

Laying out the parts pre-install

With that behind me I had a few other modifications in queue including the installing the Front Runner fuel tank I had picked up from one of the employees at Proffits Cruisers. Jeremiah had mentioned to me that Bob won a 100 aux. tank at the Cruise Moab raffle and after a few calls I figured out that it was the 62L Front Runner gravity feed tank that was originally donated to the raffle several years earlier by Paul May of Equipt Expedition Outfitters. Paul was confident in the tank as a practical and reliable solution so Bob and I were able to work out a deal and get it out to Utah. There it sat on the shelf in the shop for nearly 9 months as other more pressing projects took priority, all until this weekend. I had a Saturday morning to spare and I was able to convince Olly (my shop tech) and Jake (one of my past employees) to come spend some quality time in the shop, they took the bait. Olly and I had previously reviewed the instructions and anticipated the project taking just a few hours. We were very wrong. Between a couple of missing parts and some shall we say 'lacking' instructions, it took the better part of the day on Saturday and a few hours this morning to finish it up. In the end the extra day worked out as I was able to get some good paint coverage on the parts. The stainless steel tank's original paint was flaking bad and the more I roughed it up with scotch-brite, the worse it became to the point 1/4 or more of the paint was gone. Between the scotch-brite, fine-grit sand paper and compressed air, I as able to get the failed paint off and start priming the bare areas with a self-etching primer. I applied a couple coats of primer and then 2-3 good coats of flat black paint. I'm less than optimistic that the paint won't blow back off with the pressure washer but at least I started with a fully painted tank and access is reasonable if I need to touch it up on occasion.

Prepping the tank for re-paint

The tank mounts in place of the factory spare tire carrier and includes provisions for lowering the stock tire carrier in the event you choose to run it. I've got my spare tire on the bumper and had taken off the factory tire winch and cross-member during the original build. So while I could have utilized a much larger tank, I weighed all the options in my mind and really 62L (16 gallons) is going to work out well for my needs. Additionally, I won't be too much weight to the already heavy rear end or losing any ground clearance. A full aux tank and the additionally weight of the tank itself is roughly 150 lbs, well within the load capacity of my current springs given I'm now going to carry two less 20L Scepter fuel cans. If I find myself wanting for more fuel in the future, Long Range has a 160L auxiliary tank.

8.5mm hole in the factory main tank

Balance fitting in place

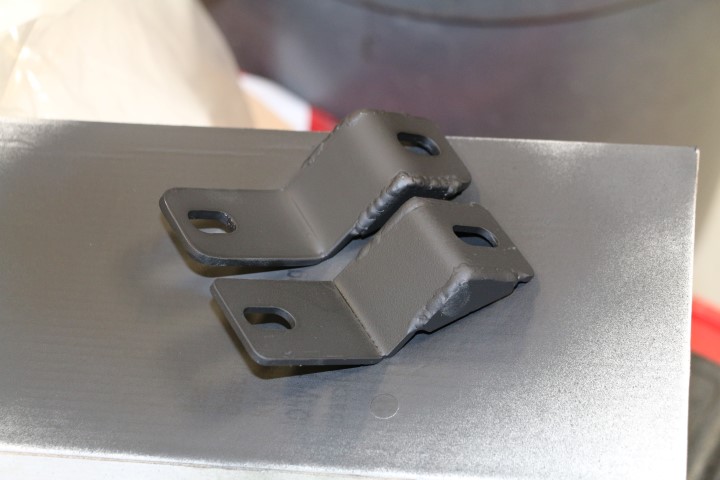

Mounting the tank was straightforward but required we clean out and re-tap 4 holes in the bottom of the body, one of which is directly above a frame cross-member leaving very little room to access the hole. The part of the project that took the most time was plumbing, more specifically adding a balance line into the lower portion of the stock tank. Front Runner includes a specialized fitting made for this application and the instructions state that it must be inserted from the inside of the tank and secured on the outside with a nut. However the inlet of the factory tank as a spring loaded 'flapper' 6-8" down the tube so even trying to fish it through with a wire proved impossible. Perhaps the non-US diesel tanks don't have the flapper and thus the lack of detail in the instructions? We ended up pulling the entire inlet/vent assembly from the tank by removing 6-7 8mm bolts and carefully separating the gasket. With that removed we had better access and could fish some bailing wire and glide the fitting it place. In hindsight, I'd likely drop the entire tank which would provide easier and safer access. We cut the factory fuel neck as directed by the instructions even adding a 1" or more of 'cushion' room as a second cut is always easier then too short. However when we went to test fit the filler system, the provided hoses were not going to work as they were shorter than the instructions part list specified which was already 1/2" shorter than we wanted ideally. It simply wasn't going to work. Fortunately NAPA had a 12" section of fuel fill hose in stock and we were back on track, thanks for making a quick parts run Jake! Somewhere along the transport, one of the mounting brackets for the tank came up missing. Its design wasn't anything difficult to duplicate but it took some time to recreate the bracket using our sheet metal brake and weld gussets into place for a near identical mount. With that behind us we went back to watching paint dry, literally.

Reproducing the the tank bracket

Painted to match

This morning we were ready to rock and roll and in just a couple of hours we had the tank mounted, finalized the plumbing and were cleaning up tools. Thanks again for spending a couple of your days off helping Olly

Tank paint completed

I drove the Cruiser out of the shop and off to the first big fill, adding ~32 gallons before the machine clicked off at $100.

I considered adding a few more to fully top off the tank but figured if there was a leak or and issue with the system, I'd rather have as little as possible to remove. I ran a few errands with it this afternoon and at each stop inspected the connections for any signs of leaking, so far it is bone dry. I'll go ahead and top off the tank tomorrow and again continue checking for any system leaks.

I am a bit worried about the proximity of the tank to the exhaust pipe, if nothing else the paint will fail and the cushion material between the tank strap and the tank might get baked? I'll likely fab up a little heat shield to help protect the tank. I'm headed out on a long road trip with a fair amount of bombing down dirt roads, it will be a great time to see just how hot the tank gets near the exhaust.

The biggest con, the total cost at the fuel pump