You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford Rebirth of a 4500

- Thread starter Ashcat

- Start date

- Location

- Richfield, UT.

Tease.

Brief KOH recap.

We made it there, ran out of time, drove it back on the trailer. No mechanical failures. 3 finished and I was scored top 20 although the corrected times don’t actually reflect physical position. Rantz couldn’t have been more than 3 positions ahead of me when the race was called.

I had a lot of fun. No ragrets. Learned a ton. I went home with a fire of determination that would burn to enormous proportions.

We made it there, ran out of time, drove it back on the trailer. No mechanical failures. 3 finished and I was scored top 20 although the corrected times don’t actually reflect physical position. Rantz couldn’t have been more than 3 positions ahead of me when the race was called.

I had a lot of fun. No ragrets. Learned a ton. I went home with a fire of determination that would burn to enormous proportions.

Last edited:

Once home the whole rig was inspected. Amazing to see your craftsmanship survive Hammers. I was in awe discovering abrasions in the most unlikely places or surfaces. Too many pictures of the inspection and said abrasions.

The number one priority was to get the shocks sorted out and continue to finish project details and better prepare the rig. However during the inspection I discovered the motor mounts were severely damaged. Inherently poor design that caved in under the stress of race conditions and poorly tuned shocks. Anyways the point of the long story is this discovery led down a rabbit hole of unexpected proportions.

The task of redesigning the mounts would require removal of the whole drivetrain so that all the bushings could be filled with dummies to establish a static load during fabrication. A decision was made that the OE floor had to go. I wanted greater serviceability and weight reduction. As time went on many ideas and things I didn’t like about the project festered. I had to cure the cancer.

It was a frustrating mind battle. I didn’t want to miss another race, trail event or season of wheeling but I couldn’t live with the many items that bothered me. Once the cab was cut free the cage became one humongous eye sore. Poor aesthetics and dead nodes everywhere. I was aware of all this but hidden in a tin can you ignore them. I wanted to fix the cage. Nope. I wanted to narrow the cab. Nope. I couldn’t figure out how to attach the skeleton cab to the existing cage. There were too many problems and the sum of the equations weren’t adding up.

Few random grindage pictures. I made huge changes in the bump stops. Arguable whether or not they should be messed with. Easy enough to revert. My opinion is they were valved worse than a brick. Last picture is the garbage stack of washers from that one guy who couldn’t tuna fish.

The number one priority was to get the shocks sorted out and continue to finish project details and better prepare the rig. However during the inspection I discovered the motor mounts were severely damaged. Inherently poor design that caved in under the stress of race conditions and poorly tuned shocks. Anyways the point of the long story is this discovery led down a rabbit hole of unexpected proportions.

The task of redesigning the mounts would require removal of the whole drivetrain so that all the bushings could be filled with dummies to establish a static load during fabrication. A decision was made that the OE floor had to go. I wanted greater serviceability and weight reduction. As time went on many ideas and things I didn’t like about the project festered. I had to cure the cancer.

It was a frustrating mind battle. I didn’t want to miss another race, trail event or season of wheeling but I couldn’t live with the many items that bothered me. Once the cab was cut free the cage became one humongous eye sore. Poor aesthetics and dead nodes everywhere. I was aware of all this but hidden in a tin can you ignore them. I wanted to fix the cage. Nope. I wanted to narrow the cab. Nope. I couldn’t figure out how to attach the skeleton cab to the existing cage. There were too many problems and the sum of the equations weren’t adding up.

Few random grindage pictures. I made huge changes in the bump stops. Arguable whether or not they should be messed with. Easy enough to revert. My opinion is they were valved worse than a brick. Last picture is the garbage stack of washers from that one guy who couldn’t tuna fish.

Last edited:

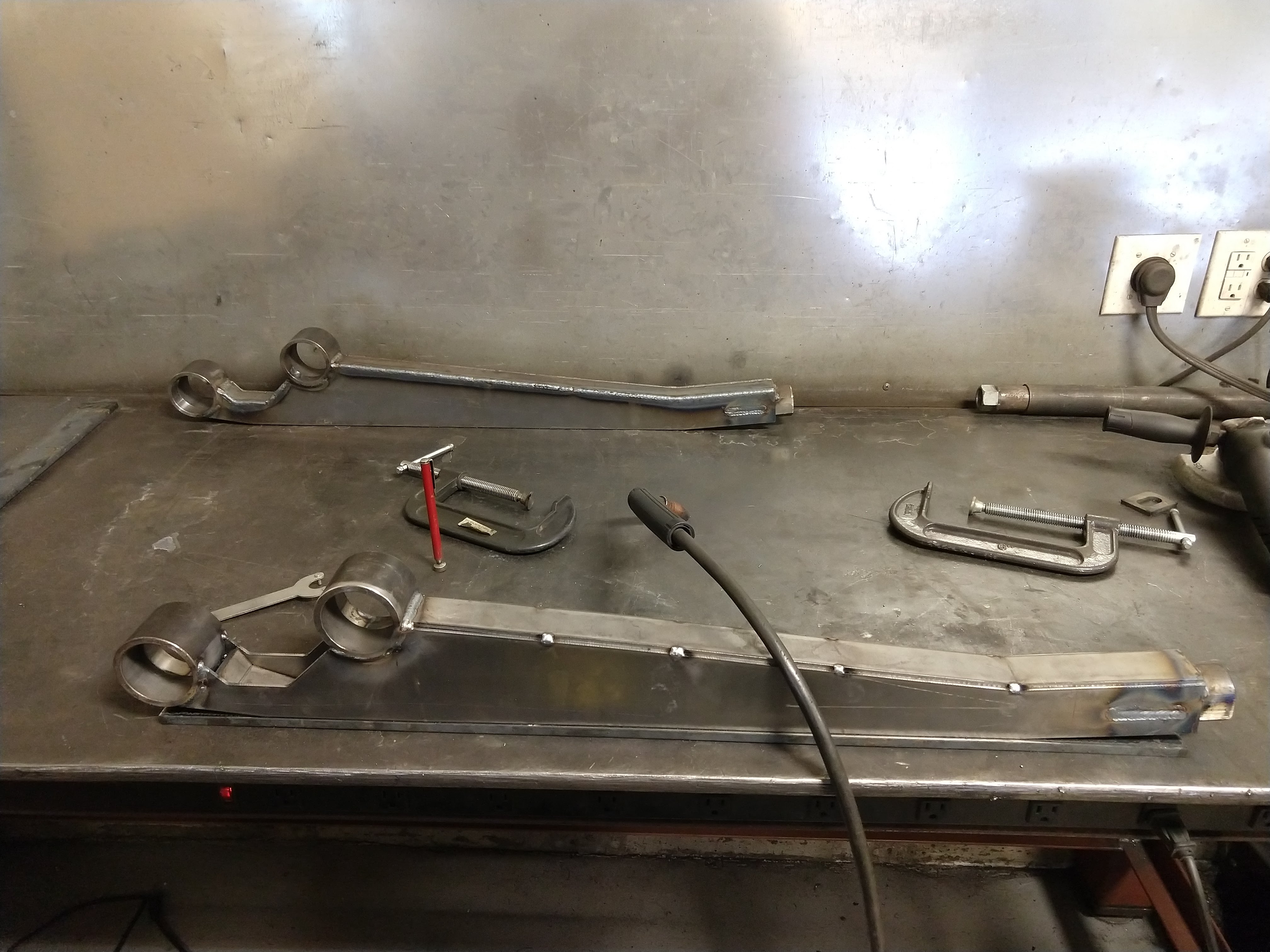

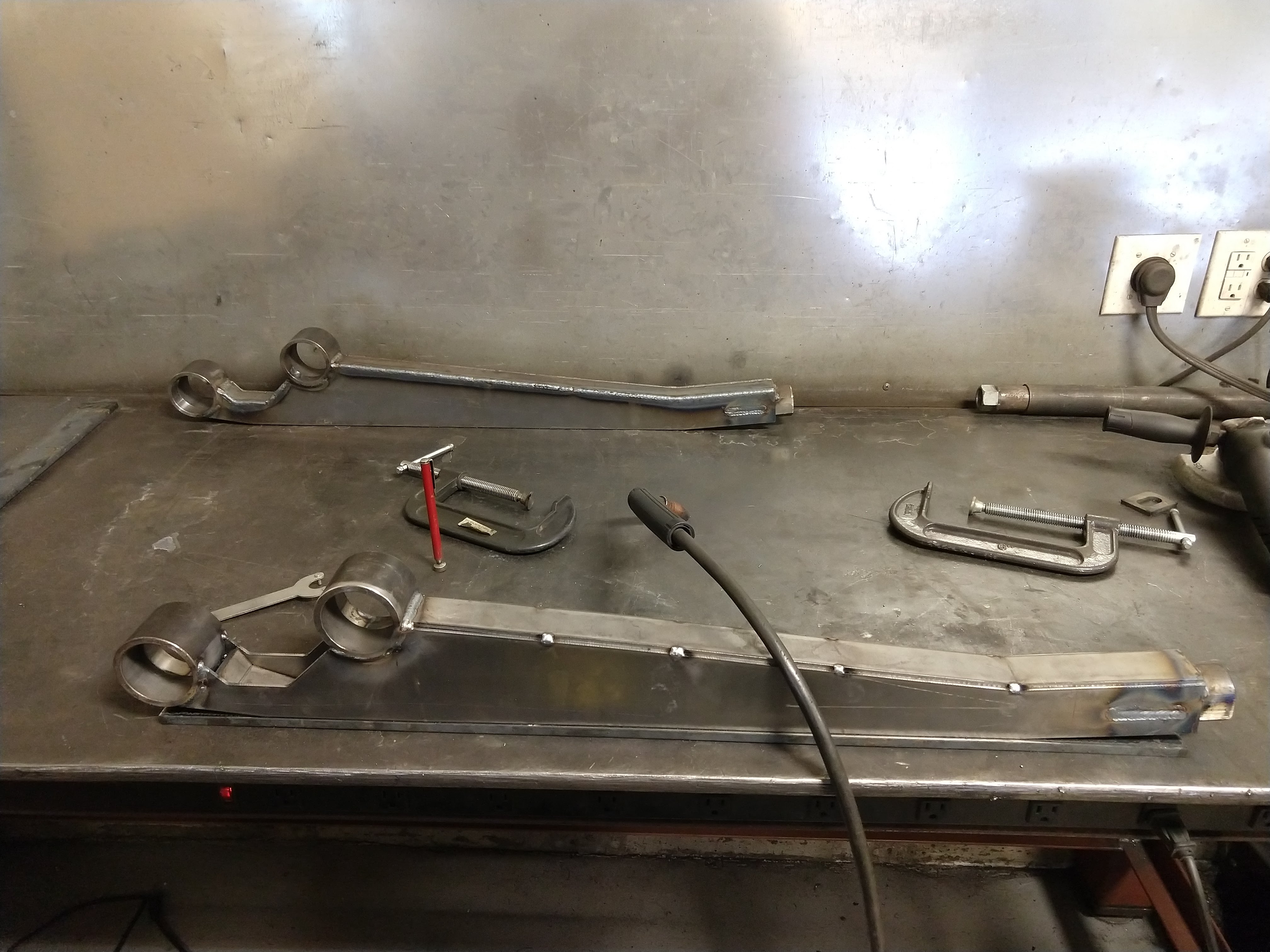

Bent mounts. Original application was imca modified chassis then I added the bushing stock. They were offset parallel but bent 20-23*

I’m actively seeking alternatives to your atypical black poly bushing. (FOR ENGINE MOUNTING) I had never used them until this project. They suck. They’re garbage. Change my mind.

I’m actively seeking alternatives to your atypical black poly bushing. (FOR ENGINE MOUNTING) I had never used them until this project. They suck. They’re garbage. Change my mind.

Last edited:

The heat and pressure destroy them. Idk whether to blame the quality, blend or durometer. The bolt sleeves all flop around in the bushing. I utilized a variety of vendor sources. They all have different mold designs or numbers from the mold. They are all trashed equally. Talking with another racer who is continuously blowing them out or splitting them, he’s going to try leaf spring bushings. I’ll try it if he has success or try a different compound of poly as in pour my own or inquire with say energy suspension and pick their brain.

I'm told racer-types use Delrin if they need a bushing-type thing in their suspension--or, just a spherical joint at all points. (either heims or uniballs)

I don't think you'll find a poly will ever hold up. And as much as I'm a fan of rubber bushings, I think the abuse of racing wouldn't agree with them either.

I don't think you'll find a poly will ever hold up. And as much as I'm a fan of rubber bushings, I think the abuse of racing wouldn't agree with them either.

I’m talking in the application of drivetrain mounting. My rig brings the beef everywhere it counts.

I don’t understand the delrin fan bois. It sounds exotic maybe? It’s plastic essentially and I only use it as a consumable wear item in a few applications.

Here’s the best picture I have of the fubar bushings. They’re not photogenic. The pen points out the wallowed out id. First photo is the engine bushings. Note the driver side caught fire. Photo below that is the transmission and transfer case support.

I don’t understand the delrin fan bois. It sounds exotic maybe? It’s plastic essentially and I only use it as a consumable wear item in a few applications.

Here’s the best picture I have of the fubar bushings. They’re not photogenic. The pen points out the wallowed out id. First photo is the engine bushings. Note the driver side caught fire. Photo below that is the transmission and transfer case support.

Last edited:

I’m talking in the application of drivetrain mounting. My rig brings the beef everywhere it counts.

Oh sorry, I misunderstood which ones were blowing out.

Yes, suspension bushings work wonderfully for motor mounts. Specifically Clevite bushings that are OEM for TJ/XJ/ZJ lower control arms, and similar. (Dodge truck LCA's use the same bushing, but with a 5/8" bolt instead of the Jeep 9/16", for example)

Sorry, it was kinda vague but I edited the post to specify. On the topic of suspension links, all of my them are 1.25 heims, 3” ballistic joints and PH & steering is 7/8 heims. I mount “small stuff” with 3/4 heims reduced to 1/2 through bolt out of convenience, cost and interchangeability throughout the rig.

Oh really? Do you have the mounting width and OD readily available? I could go either or. 5/8 would just be excessive and unnecessary weight in the fastener department. 9/16 is what I currently fasten the drivetrain with.

Oh really? Do you have the mounting width and OD readily available? I could go either or. 5/8 would just be excessive and unnecessary weight in the fastener department. 9/16 is what I currently fasten the drivetrain with.

I found them. Not horribly priced. Seems that the OD of their bushing shell is 2”? Haven’t found a MW.

Found one site that advertises them as suitable heavy duty drivetrain mounts.

Can the rubber body be pressed/released from the shell/cup? Or is it bonded in the manufacturing process?

Found one site that advertises them as suitable heavy duty drivetrain mounts.

Can the rubber body be pressed/released from the shell/cup? Or is it bonded in the manufacturing process?

The steel shell is bonded. Cheap knockoff bushings can/will separate from the metal, but good ones (genuine Clevite) will not.

2 5/8" mounting width. They fit into 2.75" .250 DOM, preferably with a little relief at one end for the step in the bushing.

Edit: I could measure once I'm at home, but from memory the bushing tube shown below is right about 2" wide.

You can see them here, as I used the same bushings for my radius arms. (but the 5/8" bolt version)

And with bushings pressed in.

You don't realistically remove the bushings without damaging them once pressed into place.

2 5/8" mounting width. They fit into 2.75" .250 DOM, preferably with a little relief at one end for the step in the bushing.

Edit: I could measure once I'm at home, but from memory the bushing tube shown below is right about 2" wide.

You can see them here, as I used the same bushings for my radius arms. (but the 5/8" bolt version)

And with bushings pressed in.

You don't realistically remove the bushings without damaging them once pressed into place.

Cool build!

I remember back in the early days of competition rock crawling, all the toyo sponsored guys would be on the trail running something else because the toyos were too hard to work very well on rocks and if they weren't being paid to run them, they wouldn't. You see lots of them these days, so it's good that they figured out the right compound.

I remember back in the early days of competition rock crawling, all the toyo sponsored guys would be on the trail running something else because the toyos were too hard to work very well on rocks and if they weren't being paid to run them, they wouldn't. You see lots of them these days, so it's good that they figured out the right compound.

They are hard which I love for the street. I’ve always sold a vehicle before needing new tires. I’ve personally ever logged 30k+ and have absolutely no doubt you’d get 55k on a pavement princess.

I’ll continue to run them for “racing” and have had mixed success crawling but I dream of treps or bfgs in the long run for all purpose crawling.

I’ll continue to run them for “racing” and have had mixed success crawling but I dream of treps or bfgs in the long run for all purpose crawling.

Here’s some random projects back when the goal was sort the rig out and make it to trailhero and KOH 2019.

A new carrier bearing shell and mounting technique

Highly modified control valve. You can’t push the limits any further than what I did in there. There’s a lot of awesome steering tech to dropped later in this thread. Maybe. And forged knuckles....

The revised assist cyl mount had a slight amount of deflection due to the size of the bracket from the crossmember so I scrounged through the bone pile and whipped up an adjustable strut to tie it in with the panhard crossmember. It’s very important for the steering gear and the panhard to be properly braced with appropriate load paths. I can compile that in another post. It’s critical for bump steer caused by deflection, death wobble and responsive, strong steering. Or I could be wrong. 99% of the internet disagrees with my ideology and experience.

And lastly, I was just about to remove the engine because I had stared at the eye cancer roll cage long enough and it was time to fabricate new engine mounts, etc. Couldn’t find my lift plate on my “Sunday” afternoon and proceeded to build one from scrap. I got this far before my wife got home and it was dinner time. Huge twist of events the following week. The engine plate was the first week of July 2018. The went dormant at that time for something like 9 months after that

A new carrier bearing shell and mounting technique

Highly modified control valve. You can’t push the limits any further than what I did in there. There’s a lot of awesome steering tech to dropped later in this thread. Maybe. And forged knuckles....

The revised assist cyl mount had a slight amount of deflection due to the size of the bracket from the crossmember so I scrounged through the bone pile and whipped up an adjustable strut to tie it in with the panhard crossmember. It’s very important for the steering gear and the panhard to be properly braced with appropriate load paths. I can compile that in another post. It’s critical for bump steer caused by deflection, death wobble and responsive, strong steering. Or I could be wrong. 99% of the internet disagrees with my ideology and experience.

And lastly, I was just about to remove the engine because I had stared at the eye cancer roll cage long enough and it was time to fabricate new engine mounts, etc. Couldn’t find my lift plate on my “Sunday” afternoon and proceeded to build one from scrap. I got this far before my wife got home and it was dinner time. Huge twist of events the following week. The engine plate was the first week of July 2018. The went dormant at that time for something like 9 months after that

Last edited:

- Location

- Richfield, UT.