Got this axle in my shop today and spent about an hour checking things out...

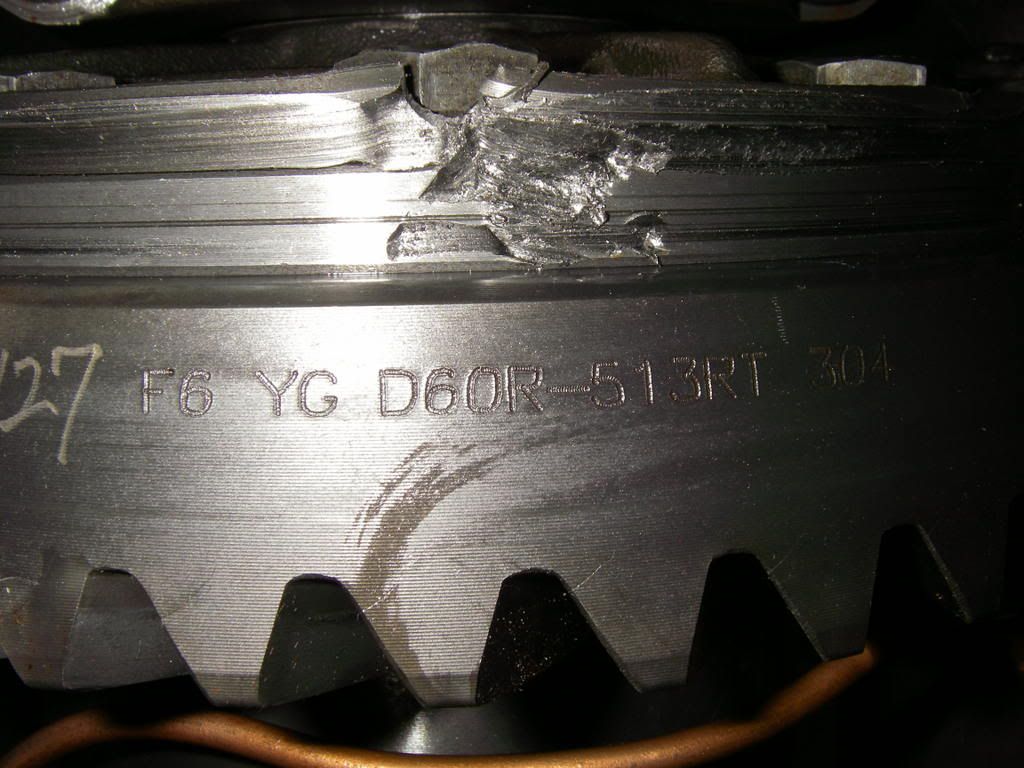

Pulled the diff cover and saw the busted teeth.

Looked at the teeth and saw the pattern on them wasn't what I would call good.

Checked the backlash and had a hard time seeing any with the masses of busted teeth, but I was able to finaly find a good spot and there was about .002" - it was very hard to hold the pinion still to check, so it might have been even less. This might explain the 'heat spot' I thought I saw in other pictures...

Put some compound on the gears and checked it, pinion is way deep. Drive side pattern is on the heel and way low in the root. Coast is on the toe.

Pulled the carrier, it had a pretty good load on it as I had to use a crow bar and 2x4, but was easier than I would have hoped - especially with an old styel ARB.

Pinion had under 5 inlb of preload on it, guage didn't move. Maybe even 0 and loose? but I couldn't feel it quite wiggle. The cage on the bearing looks spread and loose as well.

Put a depth gauge in it and verified the pinion is .007" too deep. Which in itself doesn't sound like much, but the pattern shows more - I think. ie I think it would take more than 7 thou of shims to put the pattern where I think it should be.

Then I put spacers in the carrier bearings (w/caps on) and wheel ends and stuck it - appears to be a good straight housing.

ARB is the old style and is pretty chewed up. Having a straight ring flange I think is going to be a challenge. Might have to look into a new case and repair this one? See the nice chunk missing out of the ARB flange and the cracked teeth?

Scraper is pretty chewed up from peices of gear getting caught between it and the gear/ARB.

Anyway, here's some pics... If you look at the pics close, you can see the wear pattern and where the gear isn't being used at all.

Coast side...

Drive side...

The old Precision Gear gears seemed to have about the same pattern on them....

Once again Ron at Alloy USA/Presicision Gear went above and beyond!! What a great warranty and customer service!!!! The first gears were Precisions and not only did Ron warranty them sight unseen, but he also sent out a new master install kit with the replacement gears!!! Talk about above and beyond!!!

It sounds like you don't have the pinion depth right. I would try moving the pinion in toward the ring gear, shim it until the backlash is closer to six thousandths, then read the pattern again. To me it doesn't make any sense to even look at the pattern until the backlash is right.