RogueJeepr

Here!

- Location

- Utah

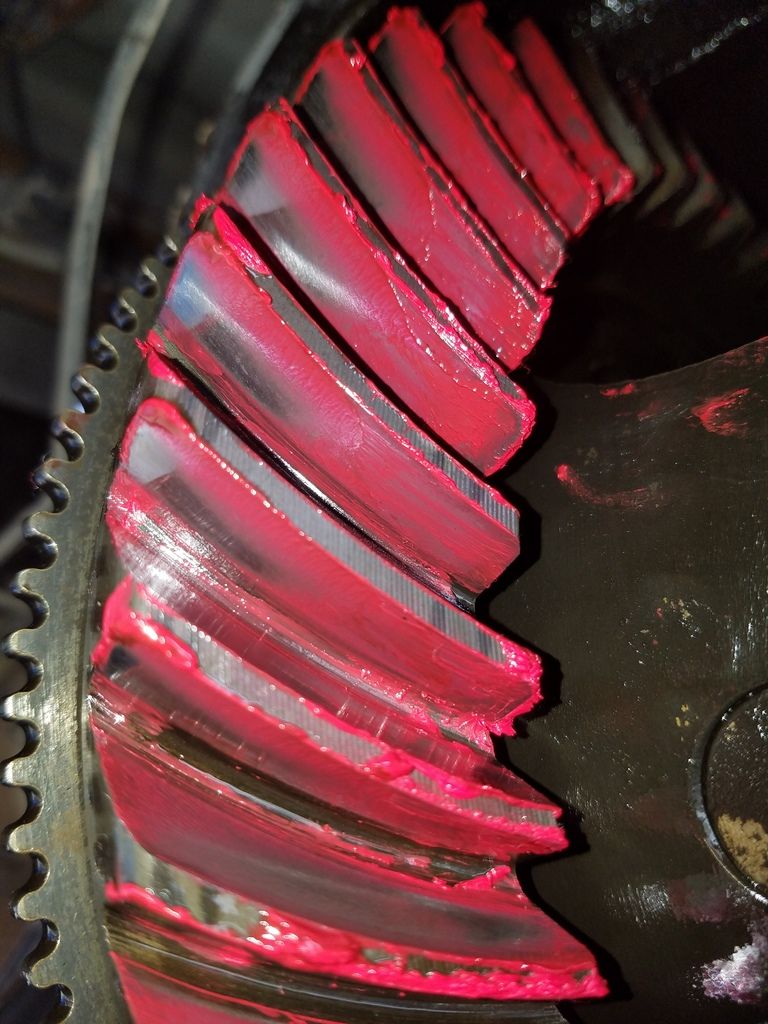

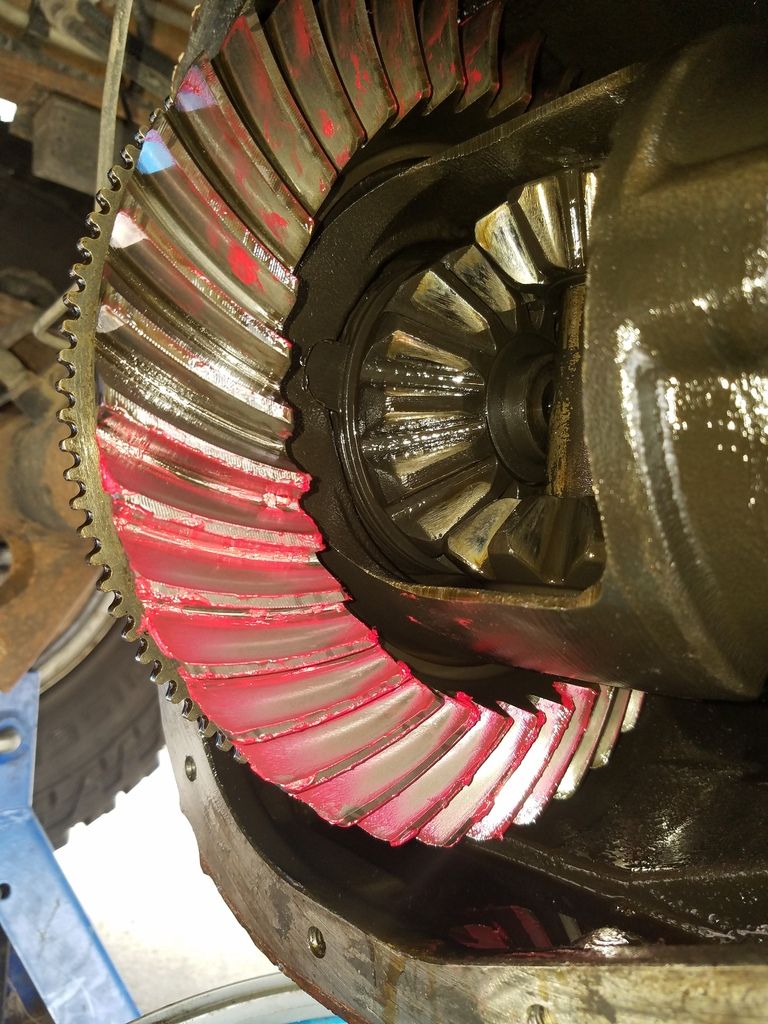

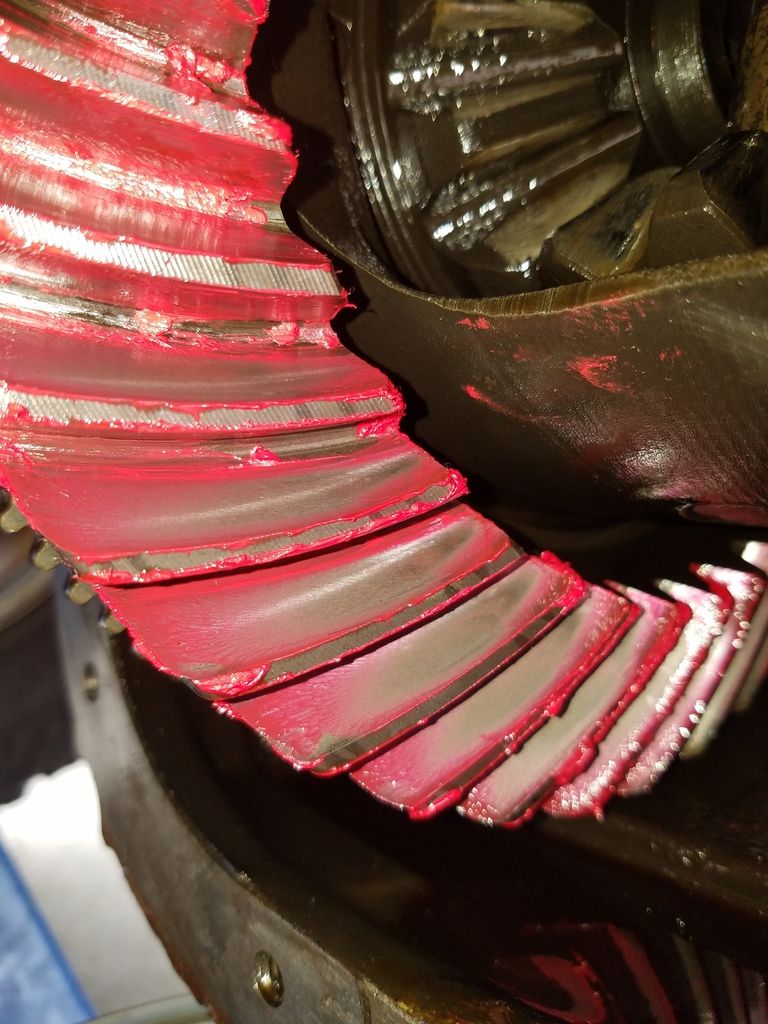

Is that paint ?

It's hard to tell with that, but it looks like it's the outside of the teeth. You'll want it more in the centered.

I know enough to be dangerous but maybe I-lean will chime in from more of a professional view.

My boss had some horrible tire hum from the rear of his Chevy which are notorious for axles going out. It was the tires.

Sent from my H1611 using Tapatalk

It's hard to tell with that, but it looks like it's the outside of the teeth. You'll want it more in the centered.

I know enough to be dangerous but maybe I-lean will chime in from more of a professional view.

My boss had some horrible tire hum from the rear of his Chevy which are notorious for axles going out. It was the tires.

Sent from my H1611 using Tapatalk

Last edited: