- Location

- Payson, UT

Hello, I am needing some help. I am not sure what my next step should be.

Context: I'm in the process of removing an Eaton E-Locker and installing a Yukon Zip locker into a Currie 60 (Rockjock 60). Below are the specs of the parts being used, as well as current setup measurements as outlined by the Yukon install instructions and video.

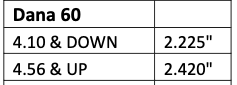

Locker PN: YZLD60-3-35 (Zip Locker for 4.10 and down)

R&P PN: Motive Gear D60-538XF (5.38 thick Gears for 4.10 and down)

Backlash: .018".

Ring Gear side shim thickness: .072"

Seal Housing side shim thickness: .014"

Minimum tolerance for seal housing side shims: .015"

I am wanting to get the backlash within spec, but am struggling to decide how to move forward from here because I do not have a sufficient seal housing side shim stack to work with. By appearances, I have the correct parts.

In this 8 year old install video by Yukon on YT, they explain that if I have a Currie 60, I need to have .120" machined off the ring gear side journal as well as the journal shoulder on that same side. The video can be seen here:

https://www.youtube.com/watch?v=E7VULdU4znI (skip forward to 8:10)

I called Yukon yesterday to verify and they confirmed that if the Currie 60 is the 1st gen housing, then the machining is warranted. However, when I call Currie, they are telling me that my housing isn't that old of a casting and no machining is required. I personally don't see how I can shift the locker to tighten the backlash without machining the locker per Yukon's recommendation.

Really trying here to check all the boxes before I pass the point of no return.

Thoughts or suggestions?

Context: I'm in the process of removing an Eaton E-Locker and installing a Yukon Zip locker into a Currie 60 (Rockjock 60). Below are the specs of the parts being used, as well as current setup measurements as outlined by the Yukon install instructions and video.

Locker PN: YZLD60-3-35 (Zip Locker for 4.10 and down)

R&P PN: Motive Gear D60-538XF (5.38 thick Gears for 4.10 and down)

Backlash: .018".

Ring Gear side shim thickness: .072"

Seal Housing side shim thickness: .014"

Minimum tolerance for seal housing side shims: .015"

I am wanting to get the backlash within spec, but am struggling to decide how to move forward from here because I do not have a sufficient seal housing side shim stack to work with. By appearances, I have the correct parts.

In this 8 year old install video by Yukon on YT, they explain that if I have a Currie 60, I need to have .120" machined off the ring gear side journal as well as the journal shoulder on that same side. The video can be seen here:

https://www.youtube.com/watch?v=E7VULdU4znI (skip forward to 8:10)

I called Yukon yesterday to verify and they confirmed that if the Currie 60 is the 1st gen housing, then the machining is warranted. However, when I call Currie, they are telling me that my housing isn't that old of a casting and no machining is required. I personally don't see how I can shift the locker to tighten the backlash without machining the locker per Yukon's recommendation.

Really trying here to check all the boxes before I pass the point of no return.

Thoughts or suggestions?