Corban_White

Well-Known Member

- Location

- Payson, AZ

More reasons why I should just go ahead and buy a printer.......I really need to block this threadGot a few more tool holders printed and installed.

View attachment 169641

View attachment 169642

View attachment 169643

View attachment 169644

View attachment 169645

Relax and let it happen.More reasons why I should just go ahead and buy a printer.......I really need to block this thread

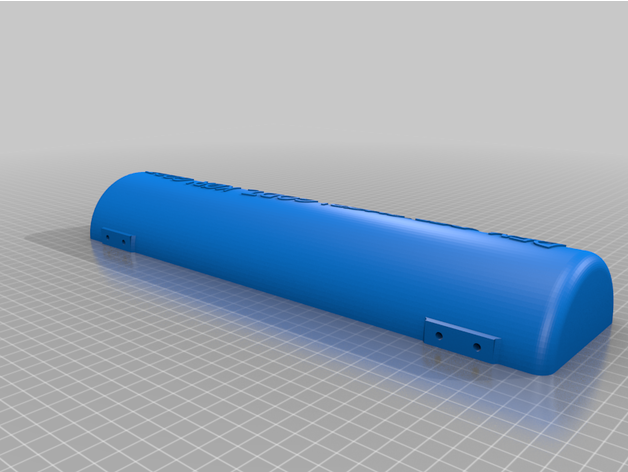

Temporary lightbar brackets until I can get a decent roofrack built.

View attachment 171046

View attachment 171048

It’s white like all the cool kids thoughFunny looking Gladiator...

Gladiator goneFunny looking Gladiator...

I still think it’s weird you’re an H2 guy but I know you like it so I’m happy for you.Gladiator gone

How'd this turn out? Might make some for my Sig......View attachment 167618

Printed a couple of these. Retention is pretty good. I'll test them out at an IDPA shoot tonight.

There are totally functional. I've used 2 of them in two shoots and not had an issue with either one.How'd this turn out? Might make some for my Sig......

Do you work at the Museum?The restoration team at the Utah Aerospace Museum is using 3D printers to recreate the leading edges on this F-117, which participated in the initial sorties of Operation Desert Storm.

The leading wing edge materials are Classified/Top Secret bits and they were removed by the USAF, so the museum is recreating them with 3D printed sections and will then paint them to look original.

View attachment 171370

View attachment 171371