jsudar

Well-Known Member

- Location

- Cedar Hills

First a little back story: I bought a 1995 K3500 four door long bed with a 454 and 4L80E. The previous owner had installed some LT1 Camaro dual electric cooling fans when the mechanical fan clutch went bad. Unfortunately, to get them to fit he trimmed the Camaro fan shroud down too far and it was basically flat against the radiator; the only place air could move through the radiator was through the fans or little around the edges where the shroud didn't cover. I figure I had lost at least 30% of the surface area of my radiator

It worked ok some of the time, if the weather was cool or I was on the freeway, but I had to run the heater full blast to make the drive up to Tibble Fork. The upper fan shroud for the mechanical fan got hacked up to make room for the electric fans and it proved to be quite difficult to find a replacement, so going back to the mechanical fan wasn't going to work. Plus, I had seen posts where guys claimed to get a 2-3 mpg improvement in fuel mileage after switching to electric fans. Since we're talking about 7000 pound truck with a big block, any help with fuel mileage would be welcomed.

An aftermarket drop-in cooling fan setup for this truck was just about $700, so that wasn't an option either.

I had a sheet of .120" aluminum from the hood of an old truggy laying around and it got me thinking. I took some measurements and realized the aluminum was large enough to cover the radiator. I already had the electric fans, so I figured I would take a shot at making my own.

The LT1 fans are twelve inch fans, but I made provisions on the shroud to fit some 14" Flex-a-lite fans if the Camaro fans don't cut it. I kind of like using factory fans because they seem to hold up pretty well.

I attached a couple pictures of the fans before (as they were installed against the radiator) and after I trimmed them to fit my new shroud and a couple of the shroud getting laid out. I will get it bent up tomorrow.

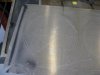

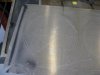

There is a long standing adage in my family that says: Don't stand behind the saw! I was cutting my aluminum to size using my table saw and the blade caught the piece being trimmed off. It sent it across the garage and stuck it through a 7/16" sheet of OSB (see the first two pix). It probably would have gone further through if it hadn't bent. That's why you don't stand behind the saw.

It worked ok some of the time, if the weather was cool or I was on the freeway, but I had to run the heater full blast to make the drive up to Tibble Fork. The upper fan shroud for the mechanical fan got hacked up to make room for the electric fans and it proved to be quite difficult to find a replacement, so going back to the mechanical fan wasn't going to work. Plus, I had seen posts where guys claimed to get a 2-3 mpg improvement in fuel mileage after switching to electric fans. Since we're talking about 7000 pound truck with a big block, any help with fuel mileage would be welcomed.

An aftermarket drop-in cooling fan setup for this truck was just about $700, so that wasn't an option either.

I had a sheet of .120" aluminum from the hood of an old truggy laying around and it got me thinking. I took some measurements and realized the aluminum was large enough to cover the radiator. I already had the electric fans, so I figured I would take a shot at making my own.

The LT1 fans are twelve inch fans, but I made provisions on the shroud to fit some 14" Flex-a-lite fans if the Camaro fans don't cut it. I kind of like using factory fans because they seem to hold up pretty well.

I attached a couple pictures of the fans before (as they were installed against the radiator) and after I trimmed them to fit my new shroud and a couple of the shroud getting laid out. I will get it bent up tomorrow.

There is a long standing adage in my family that says: Don't stand behind the saw! I was cutting my aluminum to size using my table saw and the blade caught the piece being trimmed off. It sent it across the garage and stuck it through a 7/16" sheet of OSB (see the first two pix). It probably would have gone further through if it hadn't bent. That's why you don't stand behind the saw.