Ok so this is my first build and it will be a slow one. I'm pretty new to fabrication and I don't have too many tools at home(4" angle grinder, shitty craftsman FCAW machine, and a bag full of welding tools). I am one determined little bastard though. But I did just get access at my work to use the plasma cutting table and the laser cutting table. So that will help alot.

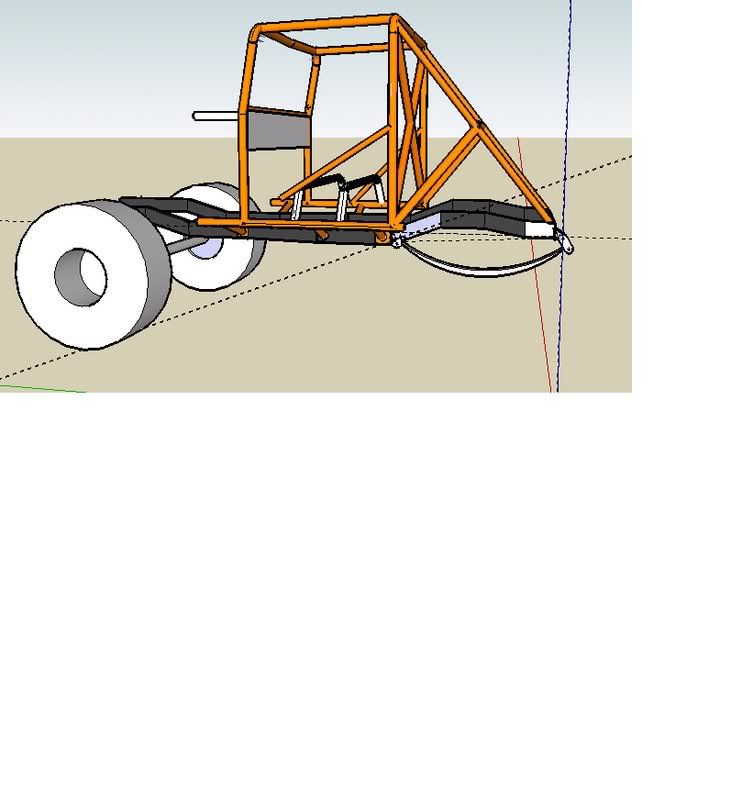

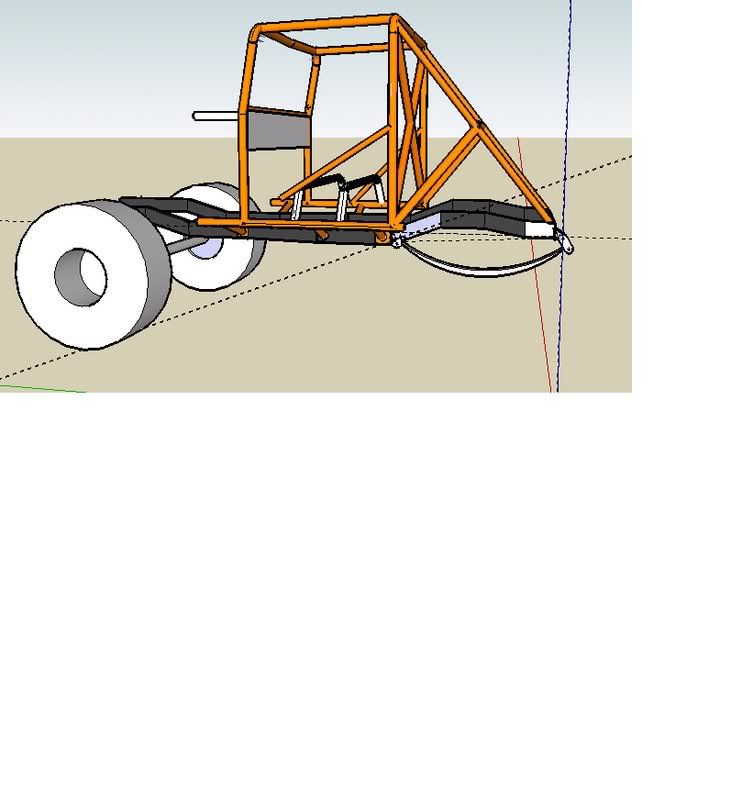

Here's what I have

1980 258 motor

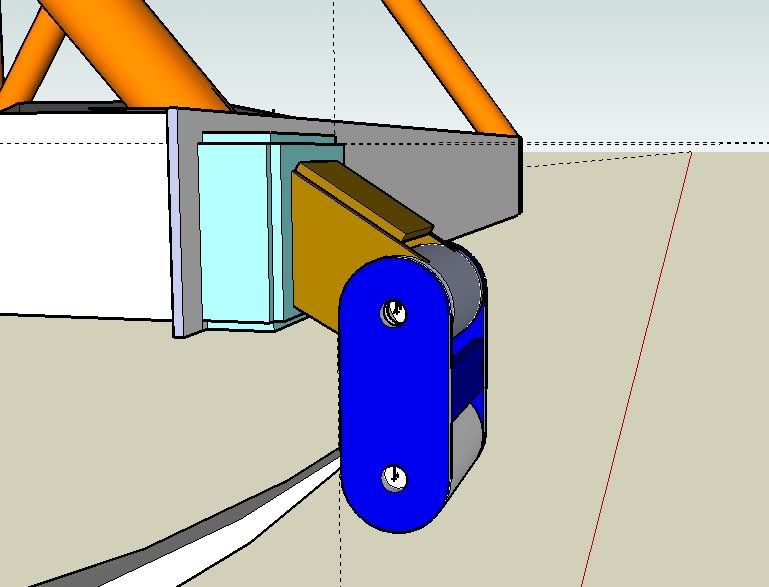

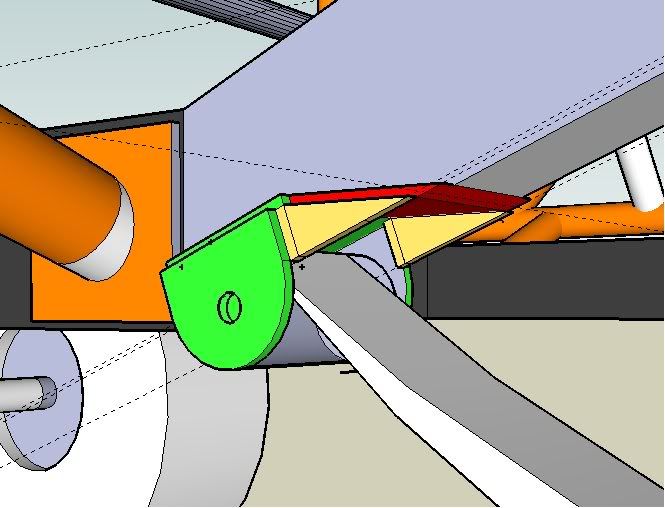

Ford t-18 tranny

dana 300 t-case

TDK CJ7 frame(2 years old)

Ford 9" 4.56 gears, spooled, 31 spline.

1.5" rubicon soa springs. rear only for now.

I am not sure what front end I am going to use right now. Having a hard time finding a chevy d60. Thinking about building a front 9" and using d60 axles if it will work. I know I have seen front 9" so there is a way and I will figure it out.

Here's what I have done so far. Tub cut from windshield back and thrown clear out into my driveway. the **** 20 gone. leaf springs streched 5" frenched lowering it about 2 inches. need to change some suspension things already though.

first pic was about 2 years ago before anything had been done to it.

Here's what I have

1980 258 motor

Ford t-18 tranny

dana 300 t-case

TDK CJ7 frame(2 years old)

Ford 9" 4.56 gears, spooled, 31 spline.

1.5" rubicon soa springs. rear only for now.

I am not sure what front end I am going to use right now. Having a hard time finding a chevy d60. Thinking about building a front 9" and using d60 axles if it will work. I know I have seen front 9" so there is a way and I will figure it out.

Here's what I have done so far. Tub cut from windshield back and thrown clear out into my driveway. the **** 20 gone. leaf springs streched 5" frenched lowering it about 2 inches. need to change some suspension things already though.

first pic was about 2 years ago before anything had been done to it.

Last edited: