RockChucker

Well-Known Member

- Location

- Highland

Let’s talk about steering. The initial concept for what I’m trying to execute came when speaking with Woodward steering about external servos back in 2014 or 2015. My brother and I had gone down the rabbit hole trying to understand how to make a better hydraulic assist. We learned about non-integral power steering and the wheels started turning. I’d already purchased a 1.75” (1.5” ID) single ended cylinder and was already on path to complete what I started. However, ever since I “finished” my Jeep about 5 years ago, I haven’t been super thrilled or in love with the hydro assist steering. This is due to a couple different things. Some due to constraints with the scout 2 steering gear and others due to poor component choices when assembling the steering gear. Here are the main ones though.

1. Steering quickener. 1.5:1 ratio to reduce the 4.25ish turn lock to lock box into roughly 2.75 turns lock to lock in practice on my Jeep. That steering speed took some getting used to. Manageable though.

2. Way too light of a torsion bar controlling the integral servo. This was just a bad choice made due to misunderstanding of the way the valve functions. Couple the light torsion bar with a fair amount of steering drag from the king pins and bronze bushings and things get quite twitchy when going around a wide sweeping bend. The light torsion bar was chosen to “maximize” flow through the control valve in the steering gear to eliminate the heavy feeling that hydro assist can have. This successfully made the steering twitchy for small inputs and didn’t eliminate the heavy feeling when steering faster than the control valve can supply fluid to the hydraulic cylinder and box.

Between the quickener’d steering and the light torsion bar, the Jeep was a manageable handful with practice. But I didn’t feel comfortable throwing the keys to say my wife and letting her cruise to the grocery store in it. Something had to be done.

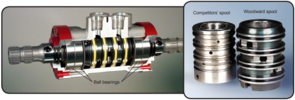

I discovered John Rants thread on pirate about the way they built the steering system on their 4500 car. This was proof positive that non-integral power steering could be made to work. The light clicked on and I realized that this would be the answer to fix the things I didn’t like about hydro assist. Taking the power out of the steering gear reduced the volume of fluid needed to flow and be pressurized by the pump. And the ports in the external servo are massive. The ports in a Saginaw box are something piddly like 1/16”. Howe and PSC port them to 1/8”. But you can’t go any larger without ruining the valve. Both the sweet valve and Woodward valve have larger ports. But the Woodward is on a whole other level. The ports have to be close to 3/8”. Now we’re talking. Should be able to fully utilize the 4.5 gpm capabilities of the pump now.

My brother and I have been messing around with this system on his Jeep for a few years. Trying to work out the bugs. He started with a single ended Howe 2.25” cylinder. With the Woodward valve, the steering felt so good. Nice and tight like a sports car. Crisp. But there were some bugs. First the tie rod rolled over at steering center because he had to run offset tie rod ends to clear the diff cover. He managed that with some anti roll spacers under the tie rod ends. But ultimately he ended up breaking jam nuts loose and there was a slight dead spot in the middle. And there was the twitch. Something in the steering system caused drag of a shudder that the servo reacted very quickly to and behaved like an undamped system. As you turn the wheel one direction, the tires generally head that way, but will twitch back and forth as they move. More annoying that anything.

Fast forward to now. He has eradicated the tie rod roll by installing a double ended ram. And narrowed the twitch down to something in the input side of the box. With my Jeep down for a bigger motor, it’s a perfect time to update the steering too.

Here’s the plan.

Woodward valve. Currently has a .210 torsion bar. This may or may not change. Part of my brother’s twitching issues could be with needing to tune the torsion bar with something larger or smaller.

•PSC 2.5x8 double ended cylinder. Was planning on using a surplus center cylinder but by the time I paid tax and shipping, it was only about $30 more to buy the PSC cylinder from radial dynamics. He had no tax and cheap shipping. This gave me flexibility in designing a mount since the cylinder can be rotated in the clamps vs the surplus center cylinder having mounting feet welded onto the body. Worth the $30 for flexibility in my opinion.

•Scout 2 steering gear still. But with some changes. One goal of the revamp is to ditch the quickener. The steering is just too fast for most to handle. So I went on a quest to figure out how to make the scout box a quick ratio. Turns out the worm screw and rack/piston out of a YJ box fits the bill. Will take the scout 4.25 turn box to a 3.25 turn box. Win! With the amount of throw my Jeep uses, it should be just under 3 turns lock to lock. Only slightly faster than a stock TJ. Perfect.

The power is being taken out of the box as well. It is easy enough to take the power out of the box. Just don’t hook hydraulics up to it. But remember the torsion bar I mentioned earlier? Well if you don’t do something about that, the steering will have a little slop in it. Solution is to weld up the torsion bar/steering input subassembly. No more twist capable. Now it will act like a solid shaft.

Have to modify the rack/piston to allow whatever lubrication medium I use to pass through it. I decided to cut the front cap off the piston allowing the lube to pass through the center around the recirculating balls.

The big question with this manual conversion has always been what to lube the box with. Initially my brother just filled his up with power steering fluid. And it has leaked like a sieve. I came across a really cool site. Might have gotten it from Brennan Metcalf. As I was poking through it, found how manual recirculating ball steering gears are lined. Packed full of moly grease. Done. I can do that. Just need to drill and tap for a zerk and an exhaust port.

As of right now, the box has been manual converted and changed to a quick ratio. The cylinder mount has been designed and racked mostly together and on to the axle and the servo will live in the same place the quickener used to be. How convenient that they are almost the exact same length.

To do list:

•Pick up a couple 7/8x3/4 heims and jam nuts for the tie rods

•Wait patiently for the tie rods to be machined

•Assemble tie rods.

•Drill and tap steering box for grease ingress/egress (might be able to use existing ports?)

•Design and build servo mount

•Cycle steering/suspension and check clearances. I already know I’m going to have to put a small 5° or so kick in the drag link. It ever so slightly contacts the cylinder clamp at full bump.

•Build hydraulic lines

•Fully weld out cylinder mount after clearances are verified.

Anywho. Thought there would be some here that would find this interesting. Feel free to ask any questions and I’ll do my best to answer. Updates to come...

1. Steering quickener. 1.5:1 ratio to reduce the 4.25ish turn lock to lock box into roughly 2.75 turns lock to lock in practice on my Jeep. That steering speed took some getting used to. Manageable though.

2. Way too light of a torsion bar controlling the integral servo. This was just a bad choice made due to misunderstanding of the way the valve functions. Couple the light torsion bar with a fair amount of steering drag from the king pins and bronze bushings and things get quite twitchy when going around a wide sweeping bend. The light torsion bar was chosen to “maximize” flow through the control valve in the steering gear to eliminate the heavy feeling that hydro assist can have. This successfully made the steering twitchy for small inputs and didn’t eliminate the heavy feeling when steering faster than the control valve can supply fluid to the hydraulic cylinder and box.

Between the quickener’d steering and the light torsion bar, the Jeep was a manageable handful with practice. But I didn’t feel comfortable throwing the keys to say my wife and letting her cruise to the grocery store in it. Something had to be done.

I discovered John Rants thread on pirate about the way they built the steering system on their 4500 car. This was proof positive that non-integral power steering could be made to work. The light clicked on and I realized that this would be the answer to fix the things I didn’t like about hydro assist. Taking the power out of the steering gear reduced the volume of fluid needed to flow and be pressurized by the pump. And the ports in the external servo are massive. The ports in a Saginaw box are something piddly like 1/16”. Howe and PSC port them to 1/8”. But you can’t go any larger without ruining the valve. Both the sweet valve and Woodward valve have larger ports. But the Woodward is on a whole other level. The ports have to be close to 3/8”. Now we’re talking. Should be able to fully utilize the 4.5 gpm capabilities of the pump now.

My brother and I have been messing around with this system on his Jeep for a few years. Trying to work out the bugs. He started with a single ended Howe 2.25” cylinder. With the Woodward valve, the steering felt so good. Nice and tight like a sports car. Crisp. But there were some bugs. First the tie rod rolled over at steering center because he had to run offset tie rod ends to clear the diff cover. He managed that with some anti roll spacers under the tie rod ends. But ultimately he ended up breaking jam nuts loose and there was a slight dead spot in the middle. And there was the twitch. Something in the steering system caused drag of a shudder that the servo reacted very quickly to and behaved like an undamped system. As you turn the wheel one direction, the tires generally head that way, but will twitch back and forth as they move. More annoying that anything.

Fast forward to now. He has eradicated the tie rod roll by installing a double ended ram. And narrowed the twitch down to something in the input side of the box. With my Jeep down for a bigger motor, it’s a perfect time to update the steering too.

Here’s the plan.

Woodward valve. Currently has a .210 torsion bar. This may or may not change. Part of my brother’s twitching issues could be with needing to tune the torsion bar with something larger or smaller.

•PSC 2.5x8 double ended cylinder. Was planning on using a surplus center cylinder but by the time I paid tax and shipping, it was only about $30 more to buy the PSC cylinder from radial dynamics. He had no tax and cheap shipping. This gave me flexibility in designing a mount since the cylinder can be rotated in the clamps vs the surplus center cylinder having mounting feet welded onto the body. Worth the $30 for flexibility in my opinion.

•Scout 2 steering gear still. But with some changes. One goal of the revamp is to ditch the quickener. The steering is just too fast for most to handle. So I went on a quest to figure out how to make the scout box a quick ratio. Turns out the worm screw and rack/piston out of a YJ box fits the bill. Will take the scout 4.25 turn box to a 3.25 turn box. Win! With the amount of throw my Jeep uses, it should be just under 3 turns lock to lock. Only slightly faster than a stock TJ. Perfect.

The power is being taken out of the box as well. It is easy enough to take the power out of the box. Just don’t hook hydraulics up to it. But remember the torsion bar I mentioned earlier? Well if you don’t do something about that, the steering will have a little slop in it. Solution is to weld up the torsion bar/steering input subassembly. No more twist capable. Now it will act like a solid shaft.

Have to modify the rack/piston to allow whatever lubrication medium I use to pass through it. I decided to cut the front cap off the piston allowing the lube to pass through the center around the recirculating balls.

The big question with this manual conversion has always been what to lube the box with. Initially my brother just filled his up with power steering fluid. And it has leaked like a sieve. I came across a really cool site. Might have gotten it from Brennan Metcalf. As I was poking through it, found how manual recirculating ball steering gears are lined. Packed full of moly grease. Done. I can do that. Just need to drill and tap for a zerk and an exhaust port.

As of right now, the box has been manual converted and changed to a quick ratio. The cylinder mount has been designed and racked mostly together and on to the axle and the servo will live in the same place the quickener used to be. How convenient that they are almost the exact same length.

To do list:

•Pick up a couple 7/8x3/4 heims and jam nuts for the tie rods

•Wait patiently for the tie rods to be machined

•Assemble tie rods.

•Drill and tap steering box for grease ingress/egress (might be able to use existing ports?)

•Design and build servo mount

•Cycle steering/suspension and check clearances. I already know I’m going to have to put a small 5° or so kick in the drag link. It ever so slightly contacts the cylinder clamp at full bump.

•Build hydraulic lines

•Fully weld out cylinder mount after clearances are verified.

Anywho. Thought there would be some here that would find this interesting. Feel free to ask any questions and I’ll do my best to answer. Updates to come...

Last edited: