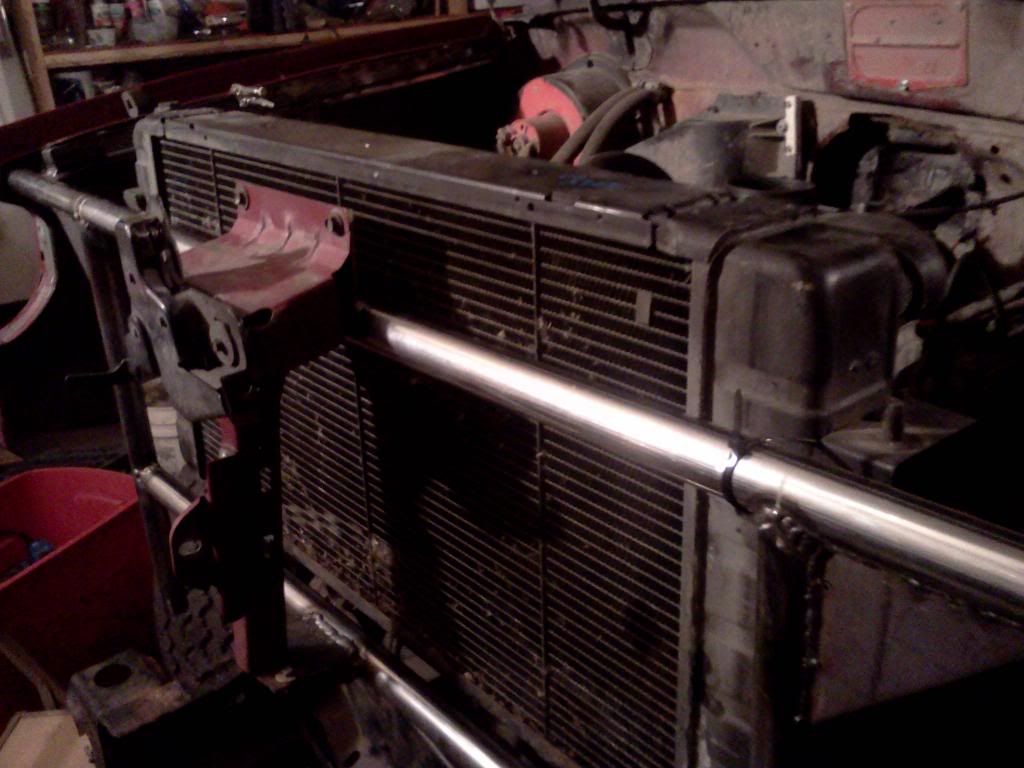

i stink like welding/grinding from working on my 3rd gen front clip swap, with tubular inner fenders

The hood is on, the fender sheet-metal work is done, and no i just need to use body-filler, and paint it. you'll notice that i opened up the arch of the fender so i would have a good factory wheel arch, that still clears my tires when they are turned. i think it is better than cutting the fenders

for lightness, and availability i went with lighter duty tube than DOM, man my cell phone's camera lense is scratched to hell so these are pretty blurry

you can't see it from this pic but i notched out the tube so it sat flat against the square plate, which gave me a better surface to weld to:

just notched the pipes together, and gusseted the corners:

i built up platforms matching the curvature of the fenders, for the fenders to bolt to:

added in some diagonals down to the firewall, attaching at the same point the stock inner fenders did:

NO HOOD PINS WILL NE NEEDED for this project (sorry rico), the hood opens, closes, and latches just like stock

the explorer hood latch is actually identical to the bronco II latch. but i just used the entire header panel bracket that holds the latch. it also holds the header panel so it made sense to just use the bracket, instead of making it all from scratch.

as you can see the new (shorter) radiator is also roughly mounted