Thanks for all your input on this topic. I like the idea of using less line on the winch drum and using the rest as an extension as needed.

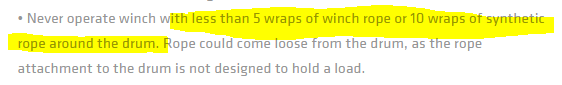

Can you tell us how many wraps of line need to stay on the drum to be safe? I always thought the entire drum needs to stay covered in wraps. If so, are the specs you listed for “first layer of drum” actually the second layer of the drum? It wouldn't make sense to advertise full strength on a layer you can’t even use.

You can absolutely use layer #1, you just don't have full use of the entire traverse, in most case just ~50% or so before it's on layer #2. So can you quickly shorten your line to stay at or near layer #1 if needed? There are tools for that too.

7-11 is the magic number I use/teach AND it's easy to remember imo

7 wraps on the drum for wire rope and 11 wraps on the drum for synthetic. That totally jives when you think about it, the wire rope has a much higher 'bite' with the drum than that of synthetic ropes with such a low coefficient of friction (but not zero). If you've ever had a winch line all the way off of a drum, you'll note the end hardware and method won't take much load at all, often a crimped on terminal and a small 1/4" or similar button head or capscrew. It's there only to keep things on the drum, it's that line's friction around the drum on the 7-11 wraps that does the work.

Now, that number will vary. Warn (and ComeUp too) say 5 for wire rope and 10 for synthetic for example.

Meanwhile Superwinch and rope manufacture Samson (Amsteel Blue) say 8 wraps for synthetic, etc. You get the point, the number will vary. I basically surveyed all credible data points I could find and use the most conservative (high # of wraps) of them all, that is the 7-11. The extra one or two wraps offered by some recommendations is just inches, hence why I prefer the more conservative and easy to remember number across all winches and lines.

As for my preferred method to attach, I like the Safe-Xtract option shown below. I like this method because event if all things go pear-shaped and you pull all the line off your drum, it doesn't rip the rope out of a terminal or bust the hardware, rather it still holds you or perhaps hold whatever item you have hanging from it. You're in a pinch to sort how you're going to start pulling that load again but at least it doesn't fall off.

You could combine this with a Gator-Jaw or similar to keep it from ever pulling off more than 11 wraps (exclusive to synthetic). Some duct tape those 11 wraps, some mark them with a special color so you know if you're at/near that layer, etc. SX puts

a 100″ red drum warning color section at the end of the Winch Line that alerts you when you are approaching max reach of your Winch Line, I really dig that option as it's so visual and easy to see from a distance. No single answer, just find something that works for you.

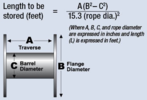

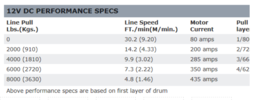

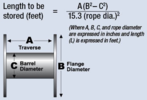

Continuing with the nerdery. If you're building your own winch rope (I'm making my own these days) or just curious how much an old winch should comfortably carry, here is a handy chart to solve for that. You could also dig up the manufacturer specs for your winch and see what it originally was equipped with... and then shorten it to make an extension