Progress! I got the new hard drive installed and everything rebuilt, that was neat.

Today I cut the supports for my slats, here's a video. It was a 6 1/2 minute really boring one, so I just trimmed it down to the first two minutes. You get the idea of what it was doing.

[youtube]qaNhKM9jMGM[/youtube]

Cutting the slat supports out was interesting, since I had to support the material without slats. But now they're in, so things will be easier now. I can also fill the table with water--I had about 1/2" in the bottom when I cut the supports, just because I didn't want to drain the full volume to install the supports.

It still collected an amazing amount of crap from cutting though...makes me really glad I built a water tray.

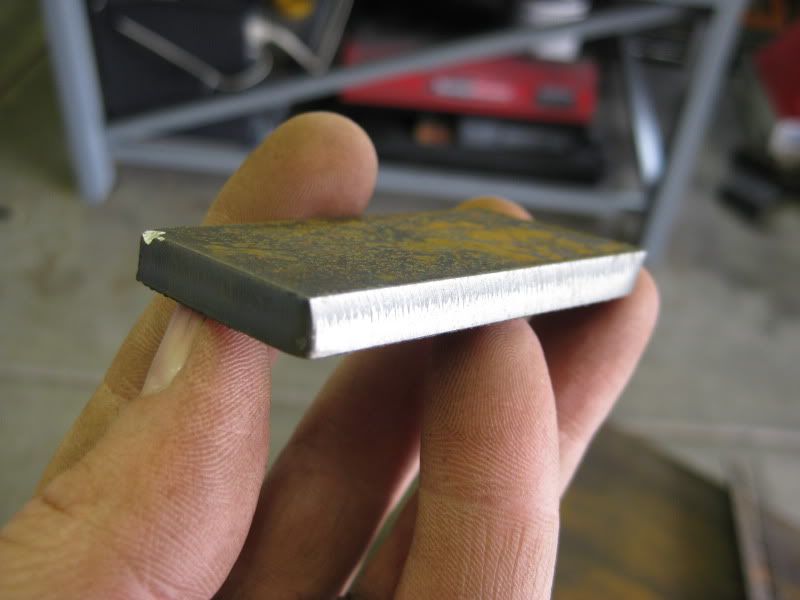

I'm pretty happy with the cut quality, considering I haven't spent much time trying to dial anything in yet! :greg:

If the dryer doesn't work I may have some ideas for you. Much cheaper than refrigerated.

I want my boat sides to say carl in them.