- Location

- Bountiful, land of rocks

That is a nice workbench you have there

It's even mobile (sorta).... flat spots collect crap

That is a nice workbench you have there

With the joys of kids driving I get to learn autobody, or at least how to fix things enough for them to drive it another day...

View attachment 164284View attachment 164283View attachment 164285

Because you are the smart.I want to buy one of these and add Super duty axles and 40" tires. Why??

Whatcha got goin on the 3-point? You may need some front ballast.My son wanted to work on the tractor, so we did.

We took the bucket off.

View attachment 164393

The bucket needs a lot of work and testing before it would ever be functional, and I wanted to use the 3 point on the tractor soon. I can do the work on the bucket without it being on the tractor.

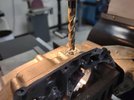

Next thing was to add a lower pedal to the clutch. With the stock pedal, you had to have your knee in your chest before it released. Now my heal can stay on the floor board and pivot like it should. Originally I was going to cut and weld the original pedal lower.. but thought the kids might want the higher pedal if they drive.

View attachment 164396

Whatcha got goin on the 3-point? You may need some front ballast.

Build a brush hog out of an old axle.I don't know yet for sure. Going to try to build my own box blade / scraper. I would love to find a brush hog... But I'm not really in the spend money mood on it yet.

I've got some pretty heavy i-beams and rail spikes.. so I think i'll make a drag with rippers if possible.

I wanted to test the 3-point lift, so I backed under a trailer and lifted the back end up... so maybe 1,000 ish lbs. No wheelie on the tractor for that.. but I'm sure it wouldn't take too much more.

Ryan’s shop truck. Used to be Tacoma’s.I wanna know more about the S10 in the driveway.

Nice save! Many would have not been able to fix that. Let alone as cleanly