- Location

- Richfield, UT.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Tech What did you work on Today?

- Thread starter Gravy

- Start date

Tonkaman

Well-Known Member

- Location

- West Jordan

Genius!Given the scarcity of shade where I seem to find myself camping, I finished my not so expo shade canopy holder (Jimmy Buffet edition)

Hitch receiver mounted, pivots side-to-side, will clear the tailgate when down, folds flat for storage. Coupled with a $40 dollar patio umbrella and I've got it made in the shade.

View attachment 120548

- Location

- The Village of Kay

pkrfctr

Registered User

- Location

- Spanish Fork, UT

Added a variable speed fan to the JKU. AEV uses the stock fan and its either off or high speed which is annoying or doesn't let the A/C work properly. I used a camaro (SPAL) fan, JSS shroud, and Lingenfelter controller. Not my design it's Todd's at JSS. Works great. Its an independent system that run off a separate coolant temp sensor to set the fan speed and has a tie into the A/C compressor to bump up the fan when the A/C kicks on.

Attachments

- Location

- West Bountiful, UT

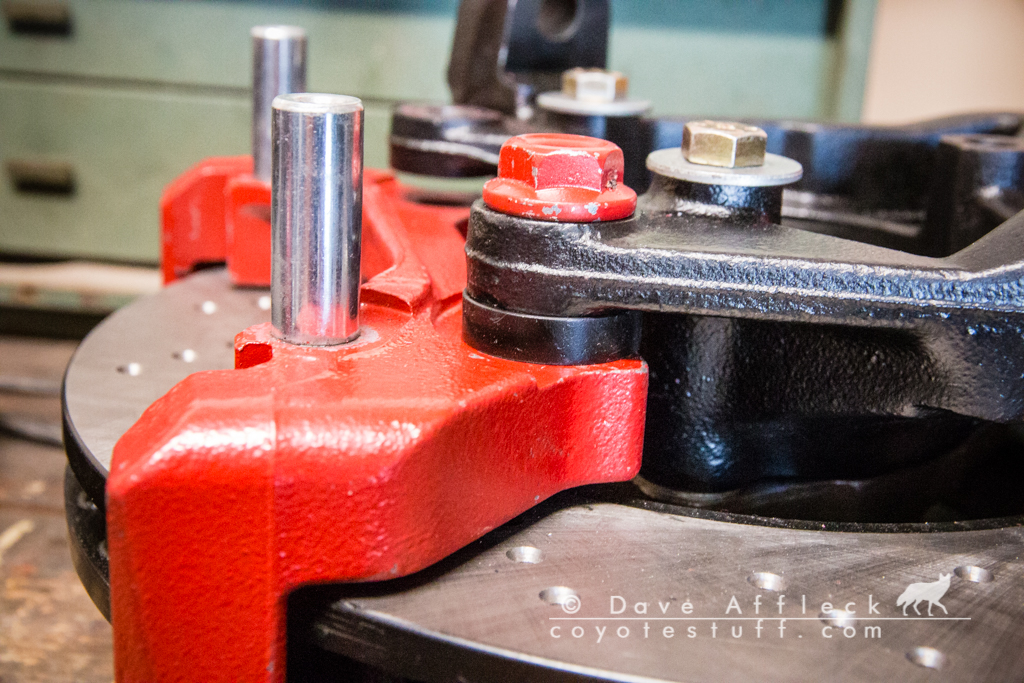

With Carl's help today, better brakes for the LJ are getting really close  .

.

- DAA

- DAA

- Location

- West Bountiful, UT

Teasers  .

.

It stops way better now .

.

- DAA

It stops way better now

- DAA

- Location

- Grand Junction, CO

Seeing the rotors side by side makes one understand how much of an upgrade that is!

4x4_Welder

Well-Known Member

- Location

- Twin Falls, ID

Very nice upgrade.

- Location

- West Haven, UT

I finally got around to completing the stand or cart for my new Branick 7600 strut spring compressor. I opted for a cart that I could store in my RV/storage bay until I needed it as I didn't want to give up a permanent spot on the wall anywhere.

Started by making a template for the wheel mounting tabs.

Then drilled the tabs.

I’m not sure if I’ve shown these before or not. Several years ago when I bought my new drill press I machined these pins that slide into the grooves of the table. One is merely to prevent the vise or work from spinning if the bit catches and the other mounts to the bottom of a vise grip style clamp. I built two of these for two separate clamps as they are much more convenient than the large wing nut that they came with for use on my last drill press. These merely slide into the groove and when clamped they offset and lock into the groove.

Wheel mounting tabs ground and ready to separate and deburr for welding.

Deciding on a location.

Base and vertical post joined.

Fabrication completed.

Wiped down with wax & grease remover and prepped for paint.

Painted and wheels installed.

Spring compressor bolted to cart.

All that is remaining is to pick up a pair of bicycle hand grips and glue them on.

Thanks for looking.

Mike

Started by making a template for the wheel mounting tabs.

Then drilled the tabs.

I’m not sure if I’ve shown these before or not. Several years ago when I bought my new drill press I machined these pins that slide into the grooves of the table. One is merely to prevent the vise or work from spinning if the bit catches and the other mounts to the bottom of a vise grip style clamp. I built two of these for two separate clamps as they are much more convenient than the large wing nut that they came with for use on my last drill press. These merely slide into the groove and when clamped they offset and lock into the groove.

Wheel mounting tabs ground and ready to separate and deburr for welding.

Deciding on a location.

Base and vertical post joined.

Fabrication completed.

Wiped down with wax & grease remover and prepped for paint.

Painted and wheels installed.

Spring compressor bolted to cart.

All that is remaining is to pick up a pair of bicycle hand grips and glue them on.

Thanks for looking.

Mike

- Location

- West Haven, UT

This was last night's project but I was able to erase another item off of my white board.

The seat belt escutcheons on the pilot and Co-pilot seats in our coach are plastic and have been cracked for the past few years but due to higher priority projects, I wasn’t able to build new ones until now. Seeing as how my wife and I are about to start our traveling for the year and I don’t want it digging into my shoulder any longer.

I started with a piece of 14-gauge P&O scribed to cut.

Cut and ready to layout lines.

I opted to use my mill so I could duplicate the plates for holes using the DRO.

Used 5/8” Roto bit to cut the holes with a smooth radius.

The mill vise work stop works great for duplicating and the ability to remove and reinstall into the vise in the exact same position.

I used a 1/2” roughing end mill and then shifted front to rear to create the 5/8” groove.

Next I opted to fabricate some inserts that would affix to the escutcheon and eliminate the ability to see the foam behind the leather, unlike the OEM ones that were pretty much just flat.

I used a piece of 5/8” 4130 tubing that I cut at about .700” long and split lengthwise to use in each slot.

Pieces ready to tack weld.

I used a piece of plate to hold the pieces together enough to tack.

Inserts welded and metal finished, ready to weld.

Sunken down from the face about .035” to create a soft edge.

Metal finished.

Test fit.

I cut a slit on each one to allow the seatbelt to fit through.

Bead blasted and painted trim black.

Thanks for looking.

Mike

The seat belt escutcheons on the pilot and Co-pilot seats in our coach are plastic and have been cracked for the past few years but due to higher priority projects, I wasn’t able to build new ones until now. Seeing as how my wife and I are about to start our traveling for the year and I don’t want it digging into my shoulder any longer.

I started with a piece of 14-gauge P&O scribed to cut.

Cut and ready to layout lines.

I opted to use my mill so I could duplicate the plates for holes using the DRO.

Used 5/8” Roto bit to cut the holes with a smooth radius.

The mill vise work stop works great for duplicating and the ability to remove and reinstall into the vise in the exact same position.

I used a 1/2” roughing end mill and then shifted front to rear to create the 5/8” groove.

Next I opted to fabricate some inserts that would affix to the escutcheon and eliminate the ability to see the foam behind the leather, unlike the OEM ones that were pretty much just flat.

I used a piece of 5/8” 4130 tubing that I cut at about .700” long and split lengthwise to use in each slot.

Pieces ready to tack weld.

I used a piece of plate to hold the pieces together enough to tack.

Inserts welded and metal finished, ready to weld.

Sunken down from the face about .035” to create a soft edge.

Metal finished.

Test fit.

I cut a slit on each one to allow the seatbelt to fit through.

Bead blasted and painted trim black.

Thanks for looking.

Mike

- Location

- West Haven, UT

Beautiful work as always. The year of traveling sounds intriguing. Any particular places or just all over?

Montana for a week of relaxing, then in August our annual trip to Ouray, September a gathering with our RV/Jeep club for a week of wheeling and then October a week in Moab with same group.

I'm itching to get off-road as I've only had my Jeep off the pavement once since the upgrades. It's been a busy first half of the year with our son buying a house and getting married so now it's time to play.

Thanks for the comments.

Mike

Montana for a week of relaxing, then in August our annual trip to Ouray, September a gathering with our RV/Jeep club for a week of wheeling and then October a week in Moab with same group.

Sounds like a great summer and fall. We're going to be Ouray on August 8th through the 11th. Can't wait for that trip.

- Location

- West Haven, UT

Sounds like a great summer and fall. We're going to be Ouray on August 8th through the 11th. Can't wait for that trip.

We'll just miss each other. I can't wait either as I look forward to our week long Ouray trip every year, this will be our 12th year in a row now. Love that place and it has been one of the few that as we are packing up to leave the wife actually mentions how much she looks forward to retirement when we can stay for several weeks or even a month there.

Mike

- Location

- Richfield, UT.

Hard to see but I mounted a winch with 2 rear mounts and 1 front mount to get the top up, then added eye bolts for ratchet straps to raise the top the little extra and secure for the summer. I had to move some lights and redo an electrical box before the project so it took much longer than anticipate. Finished the weekend project at 6:00 last night.

- Location

- The Land Northward (Bountiful), Utah

- Location

- The Land Northward (Bountiful), Utah

rholbrook

Well-Known Member

- Location

- Kaysville, Ut

I doubt she'll notice but - I'll be glad she won't bounce like a pogo stick anymore

Hmmm. Are you crazy?

- Location

- West Haven, UT

Ooooh. Gold plated.