corbin.black

Active Member

- Location

- West Jordan, Utah

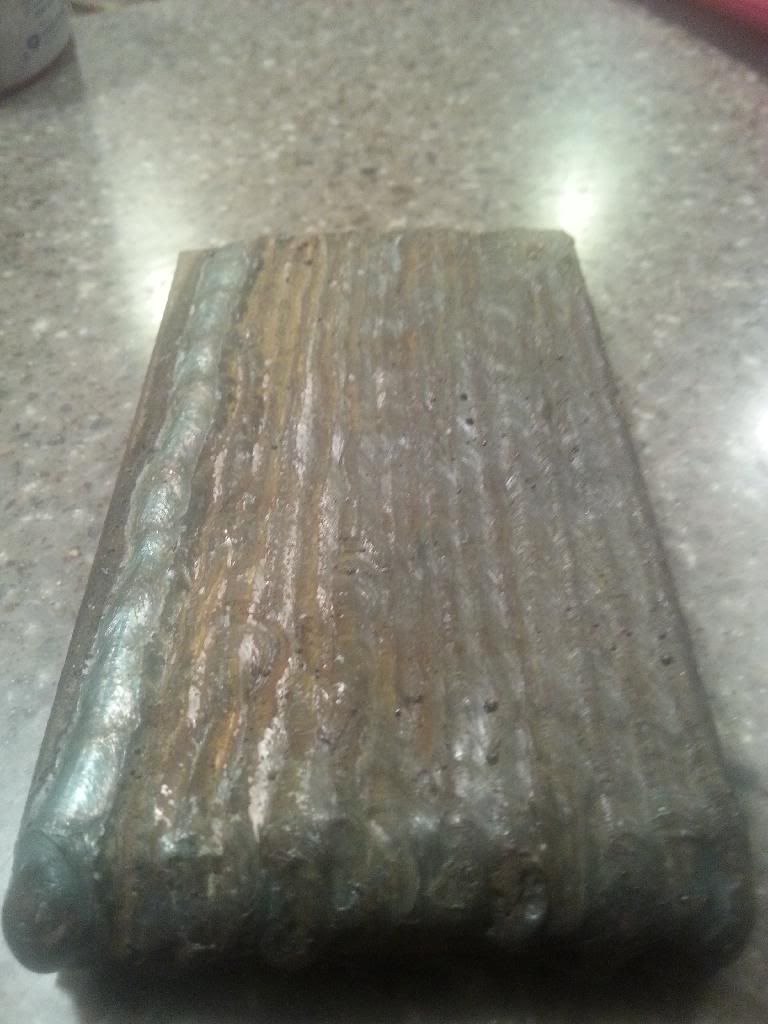

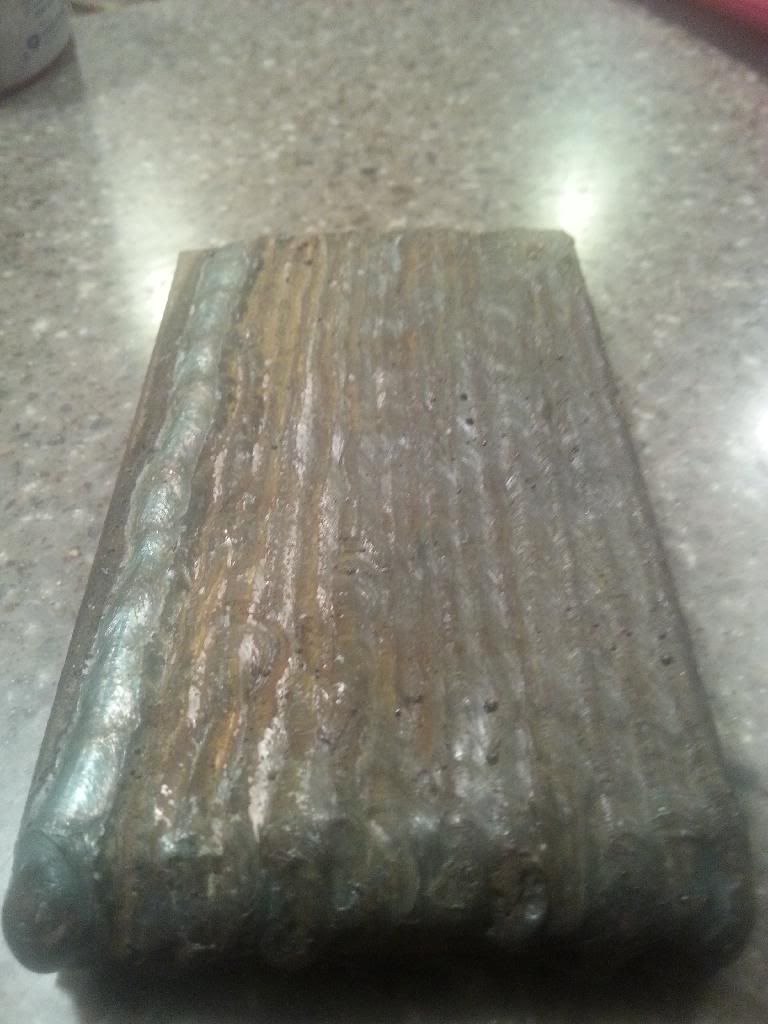

Welded up a couple more plates today in class. This first one is the same plate as before, I just finished it. And the second picture is the back side of the same plate. Front is 3/32 6010 and the back side is 3/32 7018.

So far the only thing im struggling with is not going straight across the plate. I tend to go lower and lower the further I go. Everything else seems to be going well.

Oh how I love 7018!! The slang literally just peels off by itself and there is virtually no splatter.

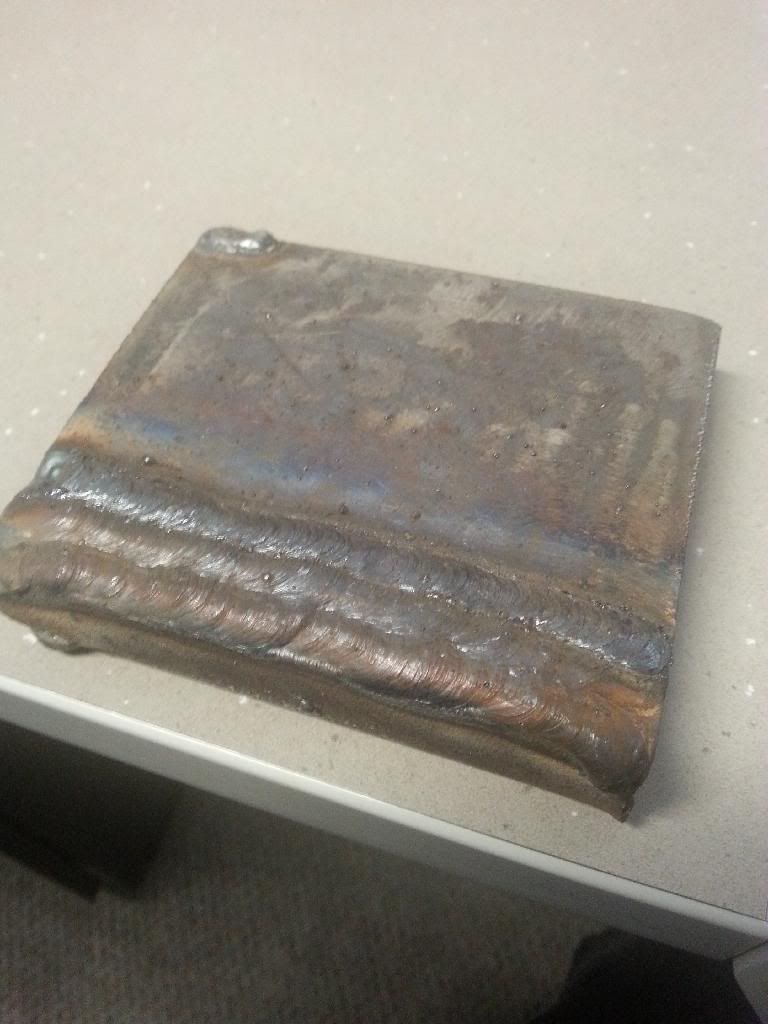

And here is the table I made to use at home. Its not pretty but it will work great.

So far the only thing im struggling with is not going straight across the plate. I tend to go lower and lower the further I go. Everything else seems to be going well.

Oh how I love 7018!! The slang literally just peels off by itself and there is virtually no splatter.

And here is the table I made to use at home. Its not pretty but it will work great.

Last edited: