sixstringsteve

Well-Known Member

- Location

- UT

Great feedback, thanks Ryan. I'll be doubling them up (or maybe even tripling). That's just the type of feedback I'm looking for. Thanks.

Last edited:

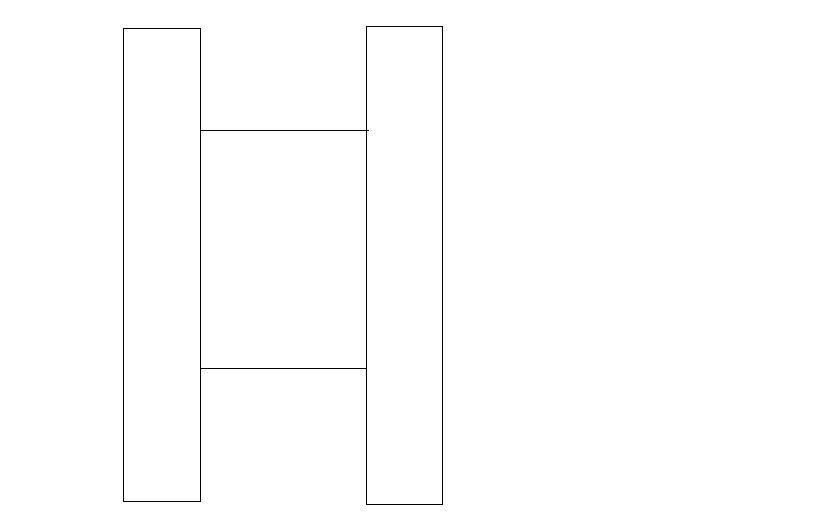

how about a gusset on the top and bottom of each, tied into the face of the bumper. Make kind of an I-beam out of it.

how about a gusset on the top and bottom of each, tied into the face of the bumper. Make kind of an I-beam out of it.

the vain side of me says that'd be too ugly.

says the man with the snorkel.. giggle, giggle

I thought this build was function over form

So you're telling me you'd go with the ibeam if it were your truck ?

Im not sacrificing any function with how I'm doing it, I'm just not choosing the ugly way.