You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just another run of the mill Buggy build

- Thread starter skippy

- Start date

-

- Tags

- build thread

- Location

- Stinkwater

That's normally a good bet.I agree with Carl

I didn't mean run a different seal...I meant so you could still use smaller shaft blank material (1.5"+ O.D.) and have a larger spot on it for the seal surface, which I think is something like 1.625".

The price in 1.5" material and 1.625 was negligible so it was worth buying the bigger material and turning it down so I can keep factory seals.

The price in 1.5" material and 1.625 was negligible so it was worth buying the bigger material and turning it down so I can keep factory seals.

Whoa that's what this was about? I changed my vote

- Location

- Bountiful, land of rocks

So…..Carl is saying skippy's shaft is too small?

....and skippy counters with measurements....

....and skippy counters with measurements....

So it's really probably like 1"

Isn't there a formula for that?

So it's really probably like 1"

Isn't there a formula for that?

...but it's an angry inch, right?

...but it's an angry inch, right?

Hahaha we're not that good of friends. Next time I see Heather I'll ask.

Hahaha we're not that good of friends. Next time I see Heather I'll ask.

She isnt shy... Ask away

I bet you guys didnt know that the face of an average spline has 20 or more different radiuses in it.... BAM skippy dropping knowledge bombs up in here

and most custom shaft manufacturers cut a straight face spline... So by cutting my own shafts I will get a stronger better and way cooler shaft

and most custom shaft manufacturers cut a straight face spline... So by cutting my own shafts I will get a stronger better and way cooler shaft

Last edited:

- Location

- Bountiful, land of rocks

So it's really probably like 1"

Isn't there a formula for that?

I've never heard women's locker room talk, but I'd assume there is some kind of theory/formula?

I bet you guys didnt know that the face of an average spline has 20 or more different radiuses in it.... BAM skippy dropping knowledge bombs up in here

and most custom shaft manufacturers cut a straight face spline... So by cutting my own shafts I will get a stronger better and way cooler shaft

Still weaker than Toyota axles

Still weaker than Toyota axles

Uh....BWAHAHAHAHAHAHAAAAAA, funny funny stuff. :greg:

Still weaker than Toyota axles

my 1" member they are talking about is stronger than a toy axle!

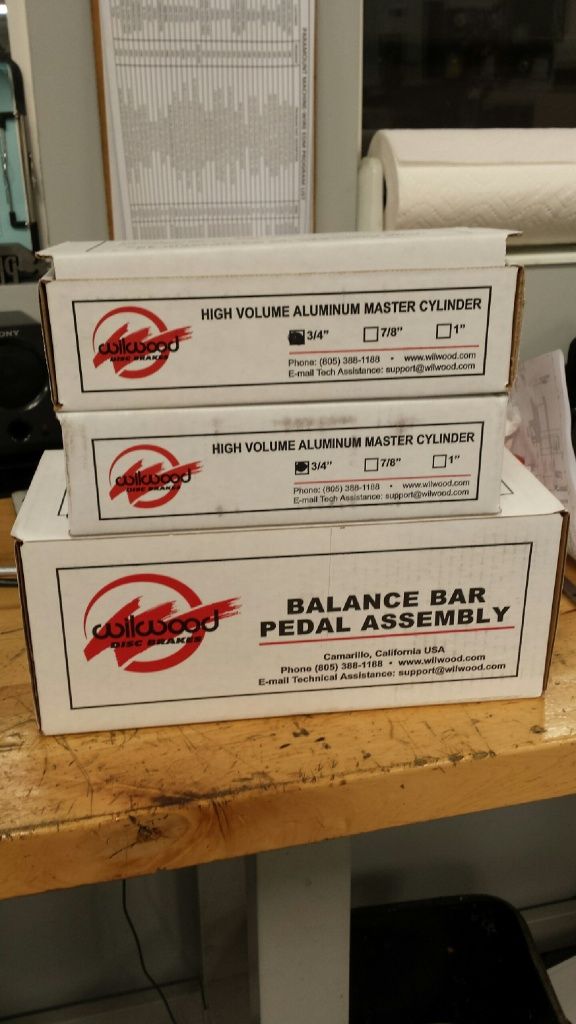

Looks similar to what I got. I went with 7/8" masters. Mine still seem spongy, and dont stop all that well, but I think it just needs to be bled more.

What style pedals? Floor mount?

I hate floor mount pedals they just feel unnatural to me, I asked around and for my brake set up i decided 3/4 would be best although i figured no matter what i did it would end up swapping them out as soon as i drove the rig.