You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Tech What did you work on Today?

- Thread starter Gravy

- Start date

Corban_White

Well-Known Member

- Location

- Payson, AZ

Hopefully take it for a shakedown soon?That is going to be so much fun. I like the valve covers.

Wait there's more, back panel in, seat belts bolted up, tossed one of the seats down just to see. Having trouble with the added leather and a seam on the pleating interfering with the window crank handle escutcheon and dropping the pin in the handle.

- Location

- The Village of Kay

About a month ago one of my double pie irons lost the pin on the hinge. Not wanting to throw it away, I remembered @cruiseroutfit telling me he had welded a new pin onto one of his cast iron pie irons.

After grinding and cleaning the area for the new pin, I pre-heated it with a propane torch before welding a new steel rod in for the hinge.

I have no idea how to tell if I got good penetration, and the welds are ugly, but fixed is fixed. If it breaks again I'm out a few minutes of time. If it holds, I get to keep using a well seasoned pie iron.

After grinding and cleaning the area for the new pin, I pre-heated it with a propane torch before welding a new steel rod in for the hinge.

I have no idea how to tell if I got good penetration, and the welds are ugly, but fixed is fixed. If it breaks again I'm out a few minutes of time. If it holds, I get to keep using a well seasoned pie iron.

- Location

- The Land Northward (Bountiful), Utah

Broken cast/ chromed bracket in a doctor's table. Not available anymore; this stuff is from the early 70's.

For a huge rush job it came out pretty strong and not too terribly ugly.

I've had more success with welding this cast then chromed stuff by grinding off the chrome, beveling then preheating and welding with flux core than any other method. (My theory is the flux core burns a bit hotter and is less sensitive to the impurities in the cast.)

For a huge rush job it came out pretty strong and not too terribly ugly.

I've had more success with welding this cast then chromed stuff by grinding off the chrome, beveling then preheating and welding with flux core than any other method. (My theory is the flux core burns a bit hotter and is less sensitive to the impurities in the cast.)

- Location

- The Land Northward (Bountiful), Utah

- Location

- Grantsville, Utah

IMPLEMENTS!!Not today, but I built a jib for our skidsteer in order for one guy to have the ability to move the stacks of precast block around the jobsite by himself without damaging the block.

I added a hitch receiver tube to the top as a way to toss in a hitch to move trailers around as well.

View attachment 170854

View attachment 170855View attachment 170857

View attachment 170856

@STAG you're not selling an '89 Wrangler are you?

Golly... "Stinger Front Bumper" may be an understatement. I'd be knocking rear windows out of cars daily pulling into parking spots.

View attachment 170761

View attachment 170762

glockman

I hate Jeep trucks

- Location

- Pleasant Grove

Chance, you constantly amaze me with the stuff that you make. It's always useful, always cool and always top notch quality.

I think you should add an air chuck to the bottom and turn this into a man sized potato artillery.

I think you should add an air chuck to the bottom and turn this into a man sized potato artillery.

- Location

- Stinkwater

- Location

- South Carolina....no public land

Finished up the wiring in the van. One goal was to make removal and install of the electrical box and external

Components easy. Therefore, powerpole connectors.

Components easy. Therefore, powerpole connectors.

I needed a sheet of wood. I wanted to avoid using plywood because of the look of the edge layers, so I was going to use solid wood and just glue planks together to get the approx 2.5’x6’ sheet that I needed.

I got a sticker shock at Home Depot that this was going to cost over $200 to do that.

So instead I bought a sheet of oak veneer plywood and mitered one edge at 45°, and cut another piece off the other side also at 45°, and glued up a false edge. Yes, I know you can buy edge banding for plywood, but I went this route. Turned out pretty good for only having a circular saw and not a table saw. Will work for what I needed it to. Almost looks good enough to look like solid wood.

I got a sticker shock at Home Depot that this was going to cost over $200 to do that.

So instead I bought a sheet of oak veneer plywood and mitered one edge at 45°, and cut another piece off the other side also at 45°, and glued up a false edge. Yes, I know you can buy edge banding for plywood, but I went this route. Turned out pretty good for only having a circular saw and not a table saw. Will work for what I needed it to. Almost looks good enough to look like solid wood.

- Location

- Grantsville, Utah

- Location

- South Carolina....no public land

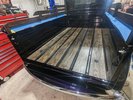

how much does that deck system weigh? just curious. Since I started driving a campervan weight is something I'm always thinking about.

- Location

- Grantsville, Utah

I believe it’s just under 200 lbs.how much does that deck system weigh? just curious. Since I started driving a campervan weight is something I'm always thinking about.

glockman

I hate Jeep trucks

- Location

- Pleasant Grove

Did I miss the post where Kevin bought an 80 series?Fished 8ga from the battery under the truck and into the cargo area. Don't think I'll ever willingly use split loom again, braided is so much cleaner.

View attachment 170888