- Location

- The Village of Kay

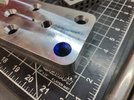

No pics, but since having 3 windshields replaced in the last few months in 3 different vehicles, my insurance dropped my comprehensive glass coverage. I got 2 rock chips on Monday in my truck. Rather than pay someone to fix the chips (since it seems to be a common occurance to get chips in my truck) I bought a repair kit and learned how to repair them myself. The kit arrived today with the practice glass I bought.

I fixed a couple of chips on the practice glass, then tackled the chips on my truck windshield.

My repairs aren't as good as a real pro would do as I think a real high quality bridge is key, but they're good enough for me and if they crack I'll try again if I can catch them in time.

It'll take many more chip repairs to pay for the kit, but at the rate I'm getting chips, that'll be in another 2-3 months or so.

I fixed a couple of chips on the practice glass, then tackled the chips on my truck windshield.

My repairs aren't as good as a real pro would do as I think a real high quality bridge is key, but they're good enough for me and if they crack I'll try again if I can catch them in time.

It'll take many more chip repairs to pay for the kit, but at the rate I'm getting chips, that'll be in another 2-3 months or so.